Blog

- Home

- Blog

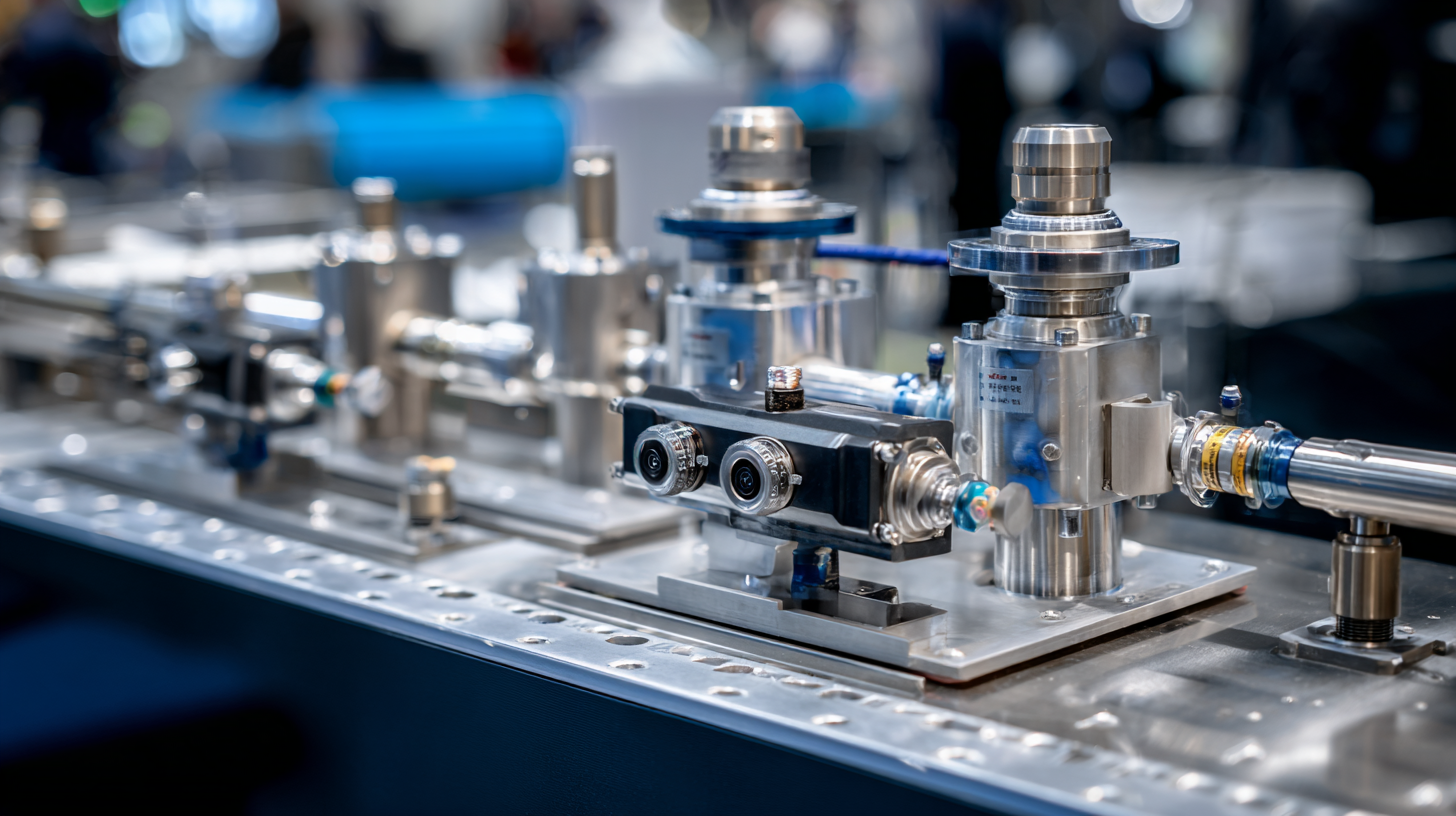

Exploring the Advantages of Single Valve Systems for Efficient Fluid Control

The adoption of single valve systems in fluid control applications has gained considerable traction in recent years, reflecting a significant shift in industry practices aimed at enhancing efficiency and reliability. According to a recent report by the International Society for Fluid Mechanics, systems using single valve configurations can reduce operational costs by up to 30% compared to traditional multi-valve setups.

With the global valve market projected to reach $85 billion by 2026, the significance of embracing single valve systems cannot be underestimated as organizations strive to stay competitive in an evolving technological landscape.

The Definition and Functionality of Single Valve Systems in Fluid Control

Single valve systems play a crucial role in efficient fluid control, particularly in modern applications such as microfluidic devices and hydraulic systems. These systems simplify the complexities often associated with multi-valve configurations by offering a streamlined mechanism that can effectively manage fluid flow. By utilizing innovative designs, such as the decoupling of the microfluidic chip from the rotating support, single valve systems can achieve bidirectional fluid movement, thereby enhancing control without the need for multiple components.

Single valve systems play a crucial role in efficient fluid control, particularly in modern applications such as microfluidic devices and hydraulic systems. These systems simplify the complexities often associated with multi-valve configurations by offering a streamlined mechanism that can effectively manage fluid flow. By utilizing innovative designs, such as the decoupling of the microfluidic chip from the rotating support, single valve systems can achieve bidirectional fluid movement, thereby enhancing control without the need for multiple components.

In addition to the straightforward functionality, single valve systems integrate advanced technologies that improve performance and energy efficiency. For instance, the adoption of variable gear ratio designs in flow control valves allows for the complete linearization of their nonlinear characteristics. This development significantly enhances their responsiveness and accuracy. Furthermore, in soft robotics applications, dynamic electrically driven soft valves are proving to be more lightweight and adaptable, facilitating the regulation of fluid-driven actuators in a compact form. Overall, the continued exploration and innovation surrounding single valve systems are essential for advancing fluid control technologies across various fields.

Key Benefits of Using Single Valve Systems for Fluid Management

Single valve systems have gained significant traction in fluid management applications due to their numerous advantages. One of the key benefits of using a single valve system is the reduction in complexity and potential points of failure. According to a report by the International Journal of Fluid Mechanics, single valve systems can decrease maintenance costs by up to 30%, as they require fewer components and simpler designs compared to multi-valve alternatives. This streamlined approach not only enhances reliability but also contributes to a lower total cost of ownership over time.

Furthermore, single valve systems offer superior efficiency in fluid control, enabling quicker response times and improved flow regulation. A study conducted by the American Society of Mechanical Engineers highlighted that implementing single valve solutions can result in a 20% increase in operational efficiency, primarily due to the minimized friction and energy losses associated with fewer moving parts. This efficiency is particularly critical in industries such as oil and gas, where precise fluid management can have substantial implications on productivity and profitability.

Advantages of Single Valve Systems for Fluid Control

Comparative Analysis: Single Valve vs. Multi-Valve Systems

In the realm of fluid control systems, the choice between single valve and multi-valve configurations can significantly impact efficiency and performance. Single valve systems offer a streamlined approach, utilizing one control point to manage fluid flow. This simplicity reduces the need for multiple actuators, which not only lowers initial installation costs but also minimizes maintenance requirements. With fewer components, the likelihood of mechanical failures decreases, leading to improved reliability in various applications.

On the other hand, multi-valve systems, while allowing for greater flexibility and control across multiple pathways, can introduce unnecessary complexity. Each additional valve requires its own actuator, which can lead to increased energy consumption and higher operational costs. Furthermore, the intricate arrangements necessary for multi-valve setups can complicate maintenance and troubleshooting efforts. By contrast, single valve systems enhance operational efficiency, making them a compelling choice for industries seeking to optimize fluid control without sacrificing reliability.

Applications of Single Valve Systems in Various Industries

Single valve systems have gained prominence across various industries due to their simplified design and efficient fluid control capabilities. In the oil and gas sector, for instance, single valve systems are employed to manage flow rates and pressure in pipelines, significantly enhancing safety and operational efficiency. By reducing the number of components, these systems minimize the risk of leaks and mechanical failures, ensuring a more reliable transportation of hazardous materials.

In the pharmaceutical industry, single valve systems are crucial for maintaining stringent hygiene standards during the mixing and dispensing of fluids. Their streamlined operation allows for precise control over fluid flow, which is vital for achieving the correct dosages in drug manufacturing. Additionally, the simplicity of these systems facilitates easier cleaning and maintenance, thereby adhering to regulatory requirements and improving overall production efficiency.

Manufacturers of beverage production systems also benefit from single valve designs, as they reduce the complexity involved in processing. This leads to quicker response times during production adjustments. Overall, the versatility of single valve systems makes them an attractive option for various applications, promoting efficiency and reliability in fluid control across multiple industries.

Potential Limitations and Considerations in Single Valve Implementation

When exploring single valve systems for fluid control, it's essential to consider the potential limitations that may arise during implementation. One primary concern is the risk of system failure, as the entire control process relies on a single point of operation. If the valve malfunctions, it can lead to significant inefficiencies or even system shutdowns. Additionally, maintaining a consistent flow rate may be challenging, as variations in pressure or temperature can impact the performance of a single valve system, necessitating careful calibration and regular monitoring.

**Tips:** Always ensure that robust maintenance schedules are in place to inspect the valve regularly. Implement backup systems or manual overrides to mitigate the risks associated with a single point of failure.

Another consideration involves the compatibility of the single valve system with existing infrastructure. Retrofitting might require additional modifications, leading to increased costs and extended downtime. Furthermore, the specific requirements of the fluids being handled—such as viscosity and corrosive properties—should be well understood, as these factors can greatly influence the valve's efficiency and longevity.

**Tips:** Evaluate the fluid characteristics thoroughly before choosing the valve solution. Engage with manufacturers to identify the most suitable single valve system that meets both operational demands and environmental conditions.

(780) 669-9420

(780) 669-9420