Blog

- Home

- Blog

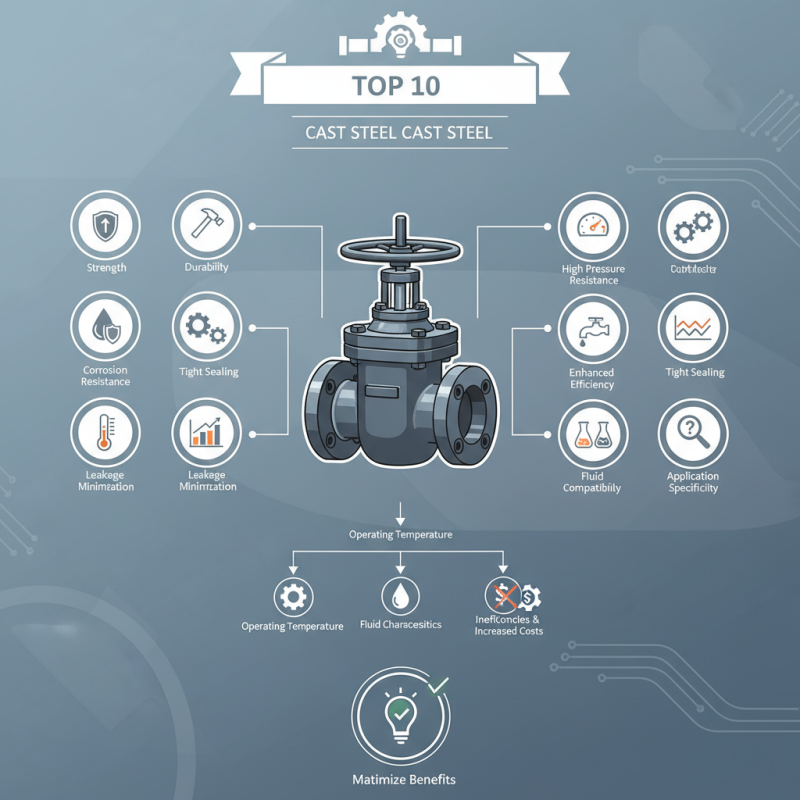

Top 10 Benefits of Cast Steel Valves for Your Industrial Applications?

In industrial applications, the choice of components can significantly impact performance. Cast steel valves have emerged as a top choice in various sectors. Their strength and durability make them suitable for demanding environments.

One of the primary benefits of cast steel valves is their ability to withstand high pressure. This trait is crucial for industries that handle fluids under extreme conditions. Additionally, cast steel valves can resist corrosion, ensuring longevity. They also offer tight sealing capabilities, which minimizes leakage and enhances efficiency.

However, selecting the right type of cast steel valves is not always straightforward. Factors like operating temperature and fluid characteristics must be considered. Making the wrong choice can lead to inefficiencies and increased costs. Despite their advantages, it’s essential to evaluate your specific needs thoroughly. Understanding these nuances is vital for maximizing the benefits of cast steel valves in your operations.

Key Durability Advantages of Cast Steel Valves in Industries

Cast steel valves are a cornerstone in many industrial applications. Their exceptional durability sets them apart in harsh environments. According to the American Society of Mechanical Engineers, cast steel offers superior resistance to wear and tear. This makes them ideal for high-pressure systems. Industries often report longer life cycles compared to other materials. For instance, cast steel valves can withstand temperatures up to 800°F without compromising integrity.

The ability to handle corrosive fluids adds another layer of functionality. A study by the Materials Research Society found that cast steel can resist corrosion in aggressive environments more effectively than alternatives. However, users should be aware that even the best materials require regular maintenance. Corrosion can still occur over time, and operators must monitor conditions. This awareness can lead to early interventions and minimize downtime.

Additionally, cast steel valves are customizable. Different configurations allow them to meet specific application needs. Some industries may find these adaptations cost-effective. However, there can be a downside. Customization sometimes leads to longer lead times. Industries must balance the need for specific designs with production timelines. Emphasizing durable materials while considering logistical impacts can lead to better overall efficiency.

Top 10 Benefits of Cast Steel Valves for Your Industrial Applications

| Benefit | Description | Industry Application |

|---|---|---|

| High Durability | Cast steel valves are resistant to wear and damage, ensuring long service life. | Oil & Gas |

| Corrosion Resistance | Coated surfaces prevent corrosion, enhancing durability in harsh environments. | Chemical Processing |

| Temperature Resilience | Withstand high temperatures, suitable for steam and hot water applications. | Power Generation |

| Cost-Effective | Lower operational costs due to fewer replacements and repairs. | Manufacturing |

| Versatile Usage | Applicable in various industries including water treatment and HVAC. | Water & Waste Management |

| Enhanced Safety | Robust design minimizes the risk of leaks and failures. | Pharmaceutical |

| Easy Maintenance | Simplified access makes routine checks and repairs easy. | Utilities |

| Wide Range of Sizes | Available in various sizes to meet different flow requirements. | Construction |

| Low Weight | Lightweight design reduces installation and handling costs. | Logistics |

| High Flow Capacity | Designed to provide efficient flow characteristics. | Mining |

Cost-Effectiveness of Cast Steel Valves Over Time

Cast steel valves offer significant cost-effectiveness for industrial applications. Research indicates that these valves can last up to 25 years with proper maintenance. This durability translates to lower replacement costs over time. Industries often face intense budget pressures. Making cost-effective choices becomes essential.

Additionally, cast steel valves withstand high pressures and temperatures. They can handle extreme conditions without compromising performance. This reliability reduces downtime, further lowering operational costs. A study by the American Society of Mechanical Engineers states that downtime can cost industries up to $250,000 per hour. Therefore, investing in durable components like cast steel valves makes financial sense.

Maintenance plays a crucial role in the long-term cost-effectiveness of cast steel valves. While initial costs may seem higher, their longevity often offsets this. Routine maintenance may involve inspections and minor repairs. Not addressing these can lead to larger expenses down the road. Balancing upfront investment with potential savings is vital in making informed decisions.

Top 10 Benefits of Cast Steel Valves for Your Industrial Applications

Resistance to Harsh Environmental Conditions with Cast Steel Valves

Cast steel valves are notable for their durability in harsh environments. These valves resist corrosion and wear, making them ideal for aggressive chemicals and extreme temperatures. Unlike other materials, cast steel maintains its integrity over time, which is crucial in industrial applications. Users often appreciate how these valves can operate effectively under high pressures.

In industries such as oil and gas, reliability is key. The need for components that withstand outdoor elements is essential. Cast steel valves show impressive resistance to rust and pitting. However, regular maintenance is still necessary. Neglecting this can lead to operational failures.

Another important aspect is the cost-effectiveness over time. Although initial investments may be higher, longevity can save on replacement costs. Down the line, the value of reduced downtime and maintenance weighs heavily. It’s worth questioning the balance between upfront costs and long-term benefits when choosing materials.

The Role of Cast Steel Valves in Enhancing System Efficiency

Cast steel valves play a crucial role in boosting system efficiency across various industrial applications. According to a report by the International Society of Automation, inefficient valve systems can lead to energy losses of up to 30%. This inefficiency significantly increases operational costs and energy waste. Cast steel valves, designed for durability and precision, mitigate such issues by ensuring optimal flow control. Their robust construction often withstands high pressures and extreme temperatures, making them ideal for critical applications.

Moreover, the ability of cast steel valves to provide tight sealing enhances process stability. A study conducted by the American Society of Mechanical Engineers highlights that an effective sealing mechanism can reduce leakage by over 90%. This results in improved system reliability and safety. However, it’s essential to select the right valve type based on specific application needs. Many industries overlook this fact, leading to performance issues and unexpected downtime. Understanding the unique requirements of each system is vital for maximizing the benefits of cast steel valves.

Ease of Maintenance and Replacement of Cast Steel Valves

Cast steel valves offer a range of benefits in industrial applications, particularly in terms of maintenance and replacement. Their robust design contributes to lower failure rates. A study found that cast steel valves can last 25% longer than alternatives. This durability means less frequent replacements, translating to cost savings.

Ease of maintenance is a major advantage. Many cast steel valves are designed for quick disassembly. This feature streamlines repairs and reduces downtime. In industries where time is money, this is vital. Operators can often replace seals or other components without complete valve removal. A report indicated that companies report a 30% reduction in maintenance costs when using these valves.

Here are some tips to consider:

- Regular inspections help identify potential issues early.

- Keep spare parts handy for swift replacements.

- Use proper tools to avoid damage during maintenance.

While cast steel valves are reliable, they may require specialized knowledge for maintenance. Not all personnel are trained accordingly. This can lead to mistakes and increased costs. It’s crucial to invest in training to maximize the benefits of these valves. Training improves safety and efficiency, ensuring a smooth operation in the long run.

Related Posts

-

Top 10 Benefits of Cast Steel Valves for Industrial Applications

-

Top Insights on Through Valve Technology for 2025 and Beyond

-

10 Best Valve Applications for Efficient Industrial Processes

-

How to Choose the Right Valve Steel for Your Industrial Applications

-

Why Forged Steel Valves Are Essential for Industrial Applications

-

Understanding Guide Valves: Their Role in Fluid Dynamics with 2023 Industry Insights

(780) 669-9420

(780) 669-9420