Blog

- Home

- Blog

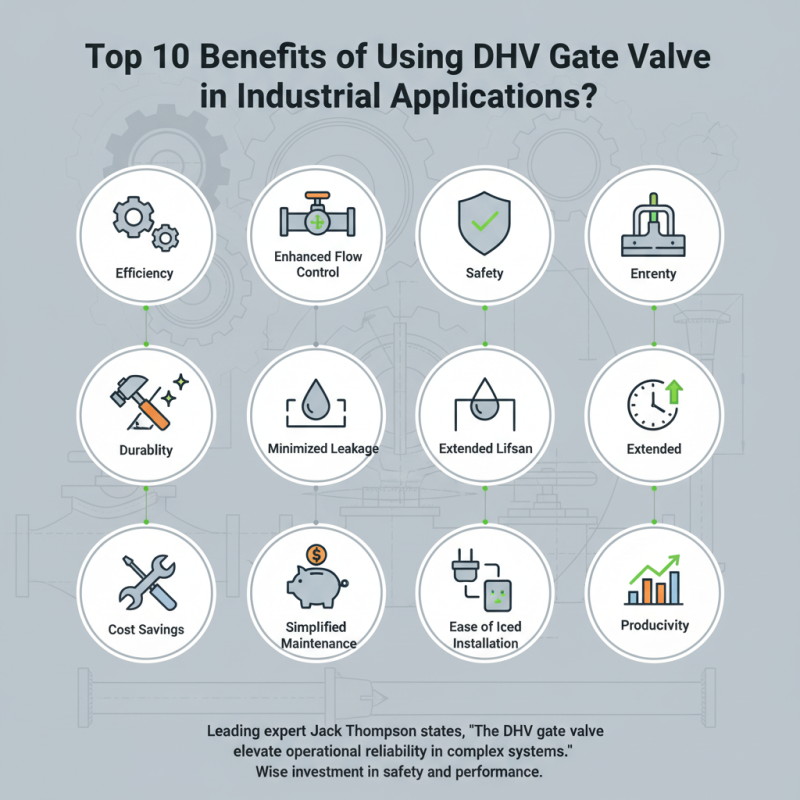

Top 10 Benefits of Using DHV Gate Valve in Industrial Applications?

In the industrial sector, efficiency and safety are paramount. The DHV gate valve stands out for its unique properties. Leading expert Jack Thompson states, "The DHV gate valve elevates operational reliability in complex systems." This highlights its vital role in diverse applications.

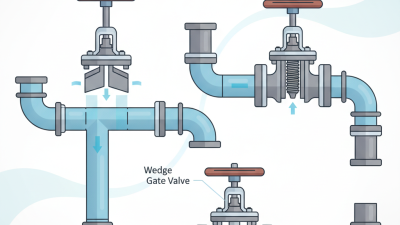

Manufacturers often underestimate the importance of valve choice. The DHV gate valve enhances flow control and minimizes leakage. It is crafted from durable materials that extend its lifespan. Reliable performance saves costs in the long run. However, improper usage can lead to failures. This is where knowledge and training come into play.

Moreover, adopting the DHV gate valve can boost productivity. Industrial operations benefit from its straightforward installation and maintenance. Users should remain vigilant about proper installation methods. Feedback from technicians can guide improvements. Choosing the right valve involves balancing quality and cost. The DHV gate valve represents a wise investment in safety and performance.

Benefits of Enhanced Flow Control with DHV Gate Valves in Industries

In industrial applications, flow control is crucial.

DHV gate valves offer significant advantages. They ensure smooth and efficient flow of liquids and gases. This aspect is vital for operations that depend on precise control.

One key benefit of DHV gate valves is their ability to minimize pressure drops.

Efficient flow can reduce energy consumption.

This leads to cost savings over time. Additionally, these valves have robust designs. They can handle high pressures and temperatures. In harsh environments, they prove reliable.

Tip: Regular maintenance can prevent unexpected failures.

Schedule inspections to ensure optimal performance.

Another important feature is the quick opening and closing mechanism.

This enhances operational efficiency. It allows for timely adjustments during processes. However, if not monitored, these adjustments may lead to wear over time.

Operators must balance efficiency and durability.

Tip: Train personnel on valve handling.

Proper usage can extend the lifespan of the valves.

Investing in DHV gate valves can transform industrial operations, but it’s essential to stay cautious.

Durability and Longevity: Statistics on Maintenance Costs and Replacement Rates

In industrial settings, durability and longevity are crucial for valve performance. The cost of maintenance can significantly impact operational budgets. Data shows that well-maintained gate valves can last over 20 years. This is more than many other types of valves. However, replacement rates can be alarming if not monitored. Neglecting regular inspections leads to costly breakdowns.

Maintenance costs for valves can vary widely. Regular upkeep might cost a few hundred dollars annually. If a valve fails, replacement can skyrocket into thousands. These statistics highlight the importance of preventive measures. Unexpected failures harm production schedules. They create safety concerns that can lead to severe disruptions.

It’s essential to assess the long-term value of DHV gate valves. Investing in quality components initially may reduce long-term costs. Many facilities find that saving on cheap alternatives leads to frequent replacements. It's a cycle that can be hard to break. Recognizing this pattern can shift how companies approach valve selection and maintenance strategies.

Top 10 Benefits of Using DHV Gate Valve in Industrial Applications

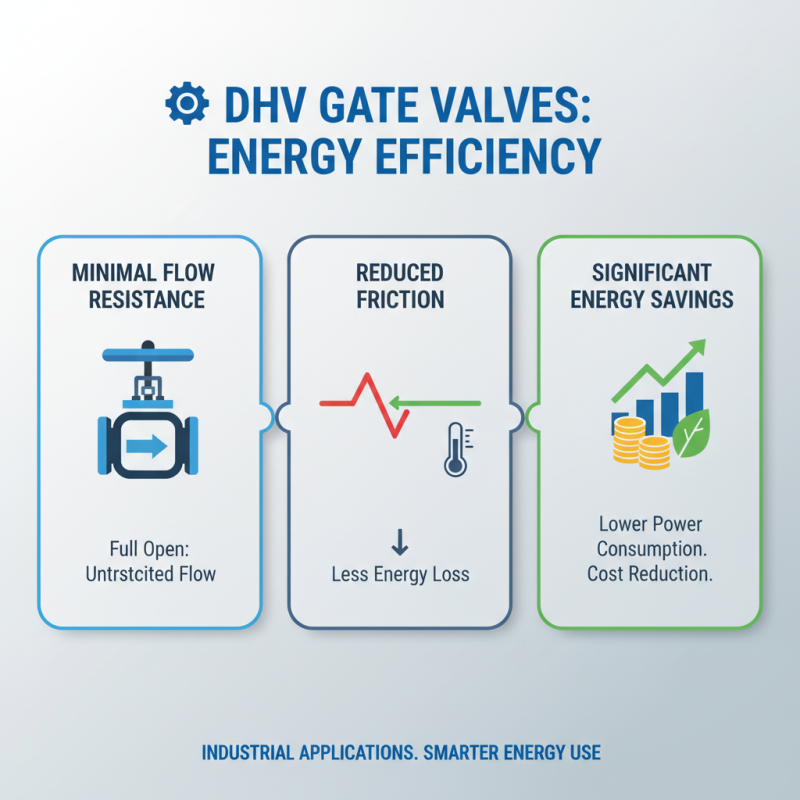

Energy Efficiency: Reducing Operational Costs Through Effective Valve Design

In industrial applications, energy efficiency is paramount. DHV gate valves can play a vital role in achieving this. Their design allows for minimal flow resistance when fully opened. This can lead to significant energy savings over time. Reduced friction means less energy is needed to transport fluids.

However, not every valve design is perfect. Sometimes, maintenance can become an issue. Regular checks are necessary to ensure optimal performance. If a valve malfunctions, it may lead to increased energy consumption instead of savings. Adjusting the operational practices around these valves can improve their efficiency even further.

Incorporating energy-efficient valves might initially seem costly. Yet, the long-term savings often justify the investment. Understanding the nuances of valve performance can lead to better operational decisions. Emphasizing energy efficiency should be a continuous process with regular assessments.

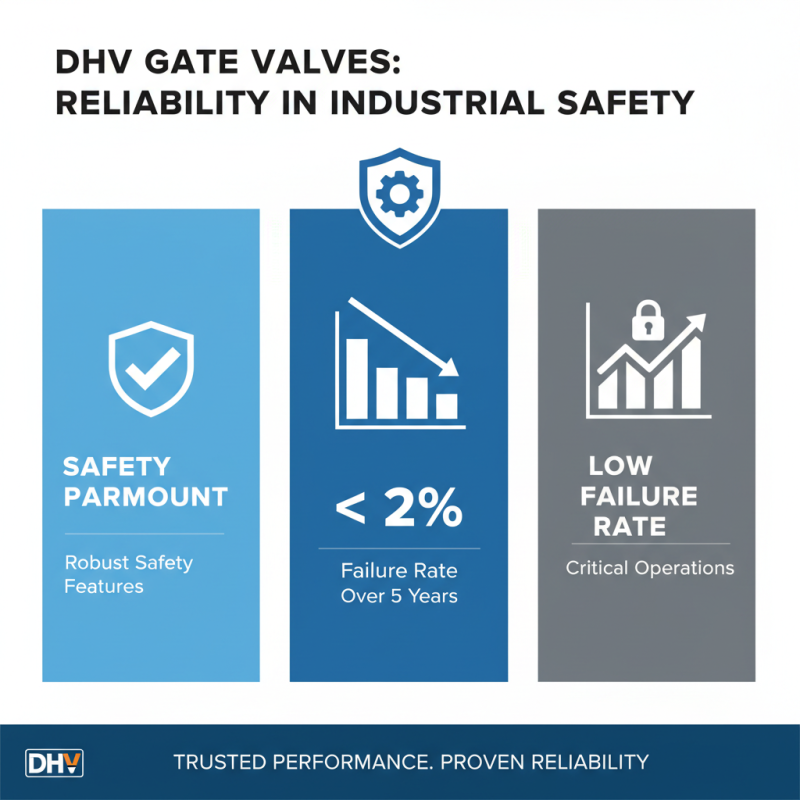

Safety Features in DHV Gate Valves: Statistics on Failure Rates and Risks

In industrial applications, safety is paramount. DHV gate valves are designed with robust safety features. Statistics show that gate valves, when maintained properly, have a low failure rate. For instance, a study indicated that the failure rate for well-maintained DHV gate valves is less than 2% over five years. This low percentage highlights their reliability in critical operations.

However, risks do exist. In environments with fluctuating temperatures, the materials may degrade over time. Regular inspections can mitigate these risks. Visual damage or signs of wear should prompt immediate action. Operators must be trained to recognize these signs early. The potential for leakage is always a concern, especially with older valves. Awareness of these issues is crucial for maintaining safety.

While DHV gate valves offer many advantages, complete safety cannot be guaranteed. Each installation comes with unique challenges. Continuous evaluation is necessary to ensure optimal performance. Addressing these imperfections can lead to improved safety outcomes. Awareness and proactive maintenance contribute to minimizing risks in industrial settings.

Applications in High-Pressure Systems: Performance Data and Industry Standards

In high-pressure systems, the choice of gate valves is critical. DHV gate valves excel in performance due to their robust design. They handle pressures ranging from 150 to 2500 PSI effectively. Such valves are built to withstand extreme conditions. They ensure tight sealing, minimizing leaks during operation. This reliability enhances overall system efficiency.

Industry standards, such as ANSI and API, highlight the importance of performance data in valve selection. A report by the American Society of Mechanical Engineers indicates that improper valve selection can lead to failures. Approximately 30% of incidents in high-pressure systems are linked to inadequate valve specifications. Such statistics underline the need for careful consideration.

Many users have observed failures in less robust valve designs over time. These failures often occur under repeated cycling conditions. A study showed that valves can fatigue after 10,000 cycles in a high-pressure environment. This presents a challenge for maintenance and operation. Users frequently find themselves replacing cheaper valves more often. Such cycles can lead to increased downtime and costs. This reinforces the value of investing in durable gate valves for long-term benefits.

Top 10 Benefits of Using DHV Gate Valve in Industrial Applications

| Benefit | Description | Performance Data | Industry Standards |

|---|---|---|---|

| High Durability | Designed to withstand high pressures and extreme conditions. | Max Pressure: 6000 psi | ASME B16.34 |

| Low Flow Resistance | Minimal obstruction to flow contributes to efficient operations. | Cv Value: 200 | API 608 |

| Versatile Applications | Suitable for various industries, including oil and gas and water treatment. | Temperature Range: -20°C to 350°C | ISO 17292 |

| Reliable Seal | Provides tight sealing, preventing leaks. | Leakage Rate: < 0.1 % | DIN 3230 |

| Easy Maintenance | Simple design allows for quick and easy maintenance and repairs. | Maintenance Interval: 3-5 years | NACE MR0175 |

| Cost-Effectiveness | Long lifespan reduces the total cost of ownership. | Average Lifespan: 20 years | API 602 |

| Temperature Resistance | Handles high temperature applications adequately. | Max Temperature: 400°C | ASME B31.3 |

| Robust Construction | Built to endure significant mechanical stress. | Material: Carbon Steel | ASTM A216 |

| Flow Control | Facilitates precise control over fluid flow. | Control Accuracy: ±5% | ISO 5208 |

| Sustainability | Materials used are often recyclable, contributing to sustainability. | Recyclability: 80% | ISO 14021 |

Related Posts

-

Top 10 Benefits of Using DHV Gate Valves for Efficient Pipeline Management

-

Why Choose a Gate Valve: Benefits and Applications in Modern Plumbing Systems

-

Best Gate Valve Types You Need to Know for Your Plumbing Projects

-

Why Choose a 4 Gate Valve for Your Industrial Applications?

-

Top 10 Benefits of Engineered Valves in Industrial Applications?

-

Top 10 Tips for Choosing the Right Valve Steel for Your Projects

(780) 669-9420

(780) 669-9420