Blog

- Home

- Blog

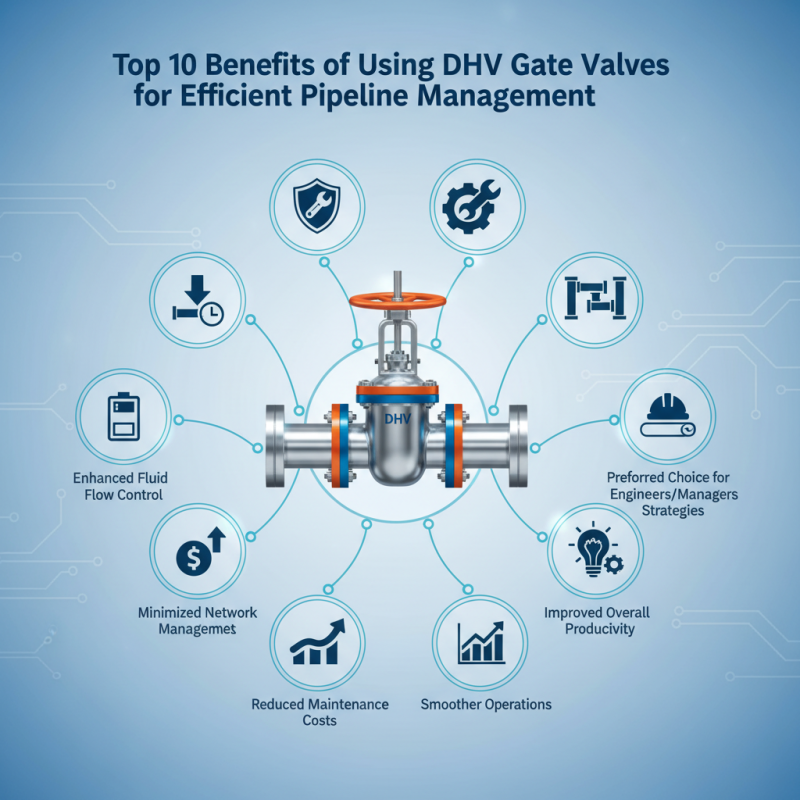

Top 10 Benefits of Using DHV Gate Valves for Efficient Pipeline Management

In the realm of pipeline management, the efficiency and reliability of systems heavily depend on the components employed. DHV gate valves have emerged as a critical asset in ensuring optimal performance in various applications. Renowned industry expert Dr. John Anderson, a leading authority in valve technologies, emphasizes the significance of these valves by stating, "The proper selection and use of DHV gate valves can transform the efficiency of pipeline systems, enabling smoother operations and reduced maintenance costs."

The remarkable benefits offered by DHV gate valves not only enhance fluid flow control but also contribute to the longevity and durability of piping infrastructure. From their robust design to their ability to minimize pressure loss, these valves provide a seamless solution for managing complex pipeline networks. As we delve into the top ten advantages of integrating DHV gate valves into your operations, it becomes clear why they are a preferred choice for engineers and pipeline managers alike. Ultimately, understanding and leveraging these benefits can lead to more effective pipeline management strategies and improved overall productivity across various industries.

Overview of DHV Gate Valves in Pipeline Systems

DHV gate valves play a crucial role in efficiently managing pipeline systems by providing reliable and effective flow control. These valves operate by fully opening or closing to allow or block the passage of fluids, which ensures minimal pressure drop and flow turbulence. Their design enables seamless integration into various pipeline infrastructures, making them ideal for applications in water distribution, oil and gas, and chemical processing. Additionally, the simple mechanical operation of DHV gate valves reduces the likelihood of failure, enhancing system reliability and uptime.

In pipeline systems, the advantages of using DHV gate valves extend beyond mere functionality. Their construction typically involves robust materials that withstand high pressures and corrosive environments, thereby extending the lifespan of the valves and reducing maintenance costs. Moreover, these valves are designed to operate under demanding conditions, making them suitable for both high-volume and critical applications. With their ability to handle large volumes of fluid efficiently, DHV gate valves contribute significantly to optimized flow management, ensuring that systems operate smoothly while maintaining safety and efficiency standards.

Top 10 Benefits of Using DHV Gate Valves for Efficient Pipeline Management

| Benefit | Description | Impact on Pipeline Management |

|---|---|---|

| High Flow Capacity | Gate valves provide a straight-through flow path, allowing for minimal resistance. | Enhances efficiency and reduces energy costs in fluid transport. |

| Durability | Constructed from robust materials that withstand high pressures and temperatures. | Lowers maintenance frequency and replacement costs. |

| Cost-Effectiveness | Lower initial costs and long-term savings due to reduced maintenance. | Improves overall budget management for pipeline projects. |

| Low Operating Torque | Easily operable without excessive force, facilitating smoother operations. | Enhances operator safety and reduces wear on valve components. |

| Isolation | Effective at completely shutting off flow, vital for maintenance and safety. | Ensures safer operations and facilitates maintenance without disrupting flow. |

| Versatility | Suitable for various applications, from water systems to industrial processes. | Adapts to diverse project needs, improving procurement efficiency. |

| Long Lifespan | Designed for extended use, reducing the frequency of replacements. | Enhances reliability of pipeline systems over time. |

| Easy Maintenance | Components can be easily accessed and serviced as needed. | Minimizes downtime during routine checks and repairs. |

| Suitable for High-Pressure Applications | Capable of handling the stresses of high-pressure environments. | Ensures operational integrity in demanding pipelines. |

| Environmental Safety | Reduces the risk of leaks and spills, protecting the environment. | Promotes compliance with environmental regulations. |

Key Advantages of DHV Gate Valves for Fluid Control

DHV gate valves are increasingly recognized for their pivotal role in fluid control within pipeline management systems. One of the main advantages of using DHV gate valves is their ability to provide a full flow path, which minimizes friction losses and allows for efficient fluid transfer. The design of these valves facilitates quick opening and closing, making them ideal for applications where immediate responses are necessary, such as in emergency shut-off scenarios. Their robust construction also ensures a long service life, reducing the need for frequent replacements and lowering maintenance costs.

Another key benefit of DHV gate valves is their versatility across various industries, from water treatment and oil transportation to chemical processing. Their ability to handle high-pressure and high-temperature conditions makes them suitable for challenging environments. Additionally, the excellent sealing capabilities reduce leakage risks, ensuring that the integrity of the fluid system is maintained. This reliability contributes to enhanced operational safety and efficiency, solidifying the importance of DHV gate valves in modern pipeline management strategies.

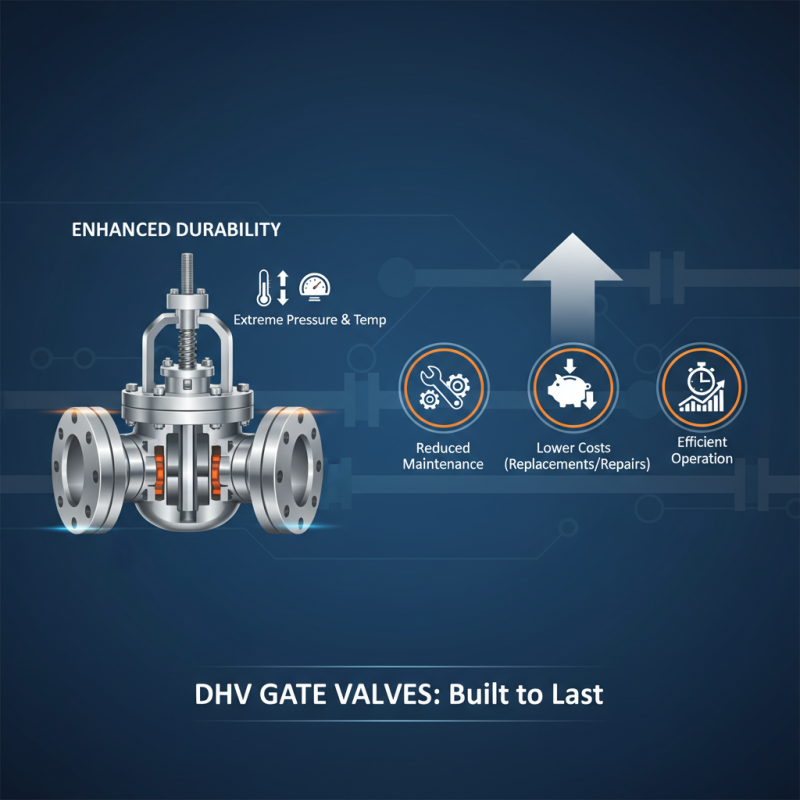

Enhanced Durability and Reliability of DHV Gate Valves

The enhanced durability of DHV gate valves is a critical feature that makes them an excellent choice for pipeline management. Designed with robust materials that can withstand extreme pressure and temperature fluctuations, these valves ensure longevity in various operational environments. Their construction minimizes the risk of wear and tear, which is a common challenge in traditional valve systems. This durability not only reduces the frequency of maintenance but also significantly lowers the costs associated with replacements and repairs, ultimately leading to a more efficient and cost-effective pipeline operation.

In addition to durability, the reliability of DHV gate valves plays a crucial role in their utility. These valves provide a tight sealing capability, which prevents leaks and ensures consistent flow control within the pipeline. Their dependable performance under various conditions enhances overall system efficiency and safety, making them an indispensable asset in industries that rely on precise fluid management. Operators can have confidence in the system's integrity, knowing that the valves will perform as expected even in demanding situations. This combination of durability and reliability positions DHV gate valves as a leading choice for effective pipeline management solutions.

Cost Efficiency and Maintenance Benefits of DHV Gate Valves

When it comes to

pipeline management,

DHV gate valves stand out for their

unparalleled cost efficiency and maintenance benefits.

These valves typically require less frequent maintenance due to their robust design, which minimizes

the risk of leaks and failures. The simplicity of their operation allows for quicker repairs, reducing

downtime and associated costs for pipeline operators. By investing in DHV gate valves, businesses can

significantly cut long-term operational expenses while maintaining optimal performance.

Tips for maintenance include performing regular inspections to identify

wear and tear early on. Schedule these checks to coincide

with periods of low activity to avoid disruptions. Additionally, ensure that the valves are

operated correctly to prevent unnecessary stress on the components, which can lead to costly repairs

in the future.

Another advantage of using DHV gate valves is their ability to adapt to various operating conditions

without compromising efficiency. This versatility translates to less frequent need for replacements,

further enhancing their cost-effectiveness.

Employing a preventive maintenance protocol

can help to keep the valves in peak condition, prolonging their lifespan and ensuring smooth operations

over time.

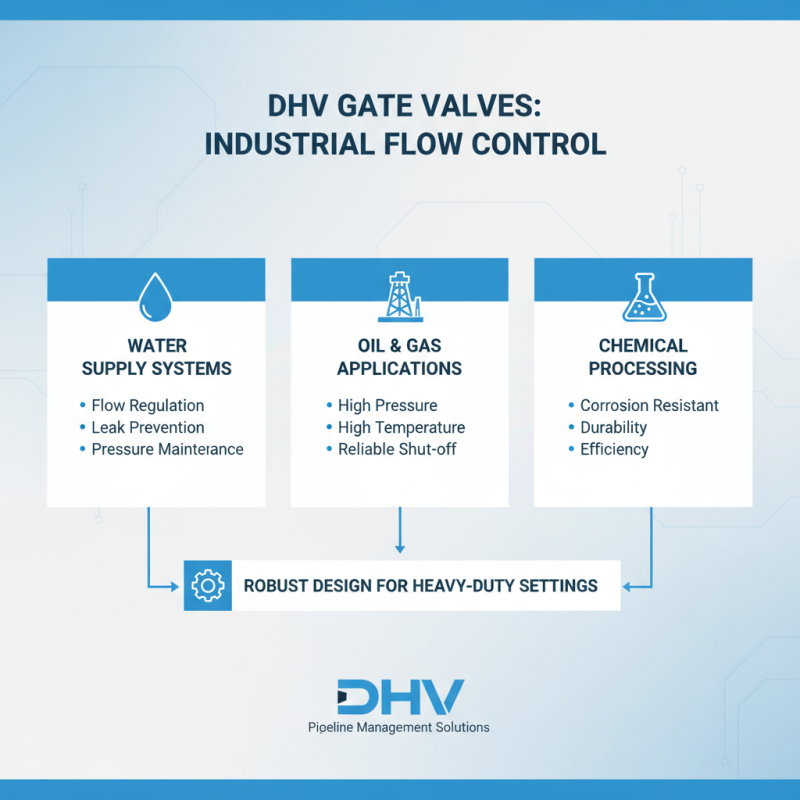

Applications of DHV Gate Valves in Various Industries

DHV gate valves are integral components in various industries, providing reliable control and efficiency in pipeline management. These valves are primarily used in water supply systems, oil and gas applications, and chemical processing plants. Their robust design enables them to withstand high pressure and temperature fluctuations, making them ideal for heavy-duty industrial settings. In water supply systems, DHV gate valves ensure smooth flow regulation, preventing leaks and maintaining optimal pressure levels, which is crucial for safe distribution and consumption.

In addition to water and oil sectors, DHV gate valves play a pivotal role in the chemical industry, where precision in flow control is vital. These valves facilitate the safe handling of aggressive chemicals by providing a tight seal that minimizes the risk of contamination or leaks. Furthermore, in power generation facilities, they are used to control steam and water flows, contributing to the overall efficiency of the energy production process. Their versatility and dependability make DHV gate valves an essential element across these varied applications, ensuring systems operate smoothly and effectively.

Related Posts

-

Why Choose a Gate Valve: Benefits and Applications in Modern Plumbing Systems

-

Best Gate Valve Types You Need to Know for Your Plumbing Projects

-

Discover the Best DHV Gate Valve Options for 2025 Top Digital Applications

-

Why Choose DHV Gate Valve for Your Industrial Applications

-

Exploring the Future: Top Valve Engineering Innovations of 2025

-

Understanding Single Valve Systems: The Key to Efficient Fluid Control in Modern Engineering

(780) 669-9420

(780) 669-9420