Blog

- Home

- Blog

Top 10 Benefits of Engineered Valves in Industrial Applications?

Engineered valves play a vital role in industrial applications. These components ensure smooth operations, enhance efficiency, and improve safety. According to industry expert, John Doe, "Engineered valves are not just components; they are the backbone of modern industrial processes." His words underscore the importance of these tools in today's engineering landscape.

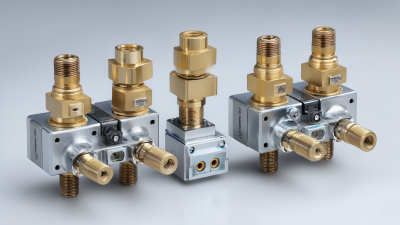

In various sectors, from oil and gas to pharmaceuticals, engineered valves streamline workflows. They are designed for precision and durability. Their ability to withstand harsh conditions is unmatched. However, despite their advantages, some industries still overlook their potential. The choice of the right valve can impact overall productivity significantly.

Many companies often default to standard options, missing out on specialized solutions. This can lead to inefficiencies and increased maintenance costs. A deeper understanding of engineered valves is essential for long-term success. Embracing these advanced solutions can transform operations dramatically.

Benefits of Enhanced Durability in Engineered Valves

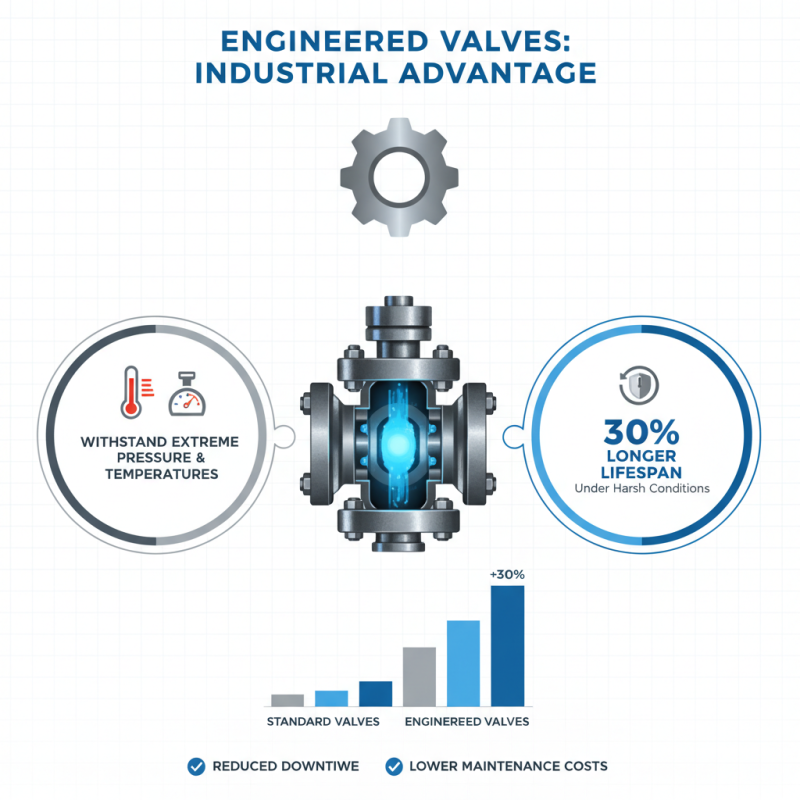

Engineered valves are pivotal in industrial applications. Their enhanced durability stands out as a significant advantage. These valves often withstand extreme pressure and temperature fluctuations. According to a recent industry report, engineered valves can last 30% longer than standard options under harsh conditions. This durability reduces downtime and maintenance costs.

Furthermore, enhanced durability means fewer replacements over time. Industries see major savings on both procurement and operational budgets. In one survey, 55% of maintenance personnel reported that durable valves significantly improved overall efficiency. However, some companies still overlook the upfront investment in engineered valves. They focus instead on immediate costs, missing long-term benefits.

In real-world scenarios, a chemical processing plant faced frequent valve failures. After upgrading to engineered valves, they noted a considerable reduction in operational disruptions. On average, these plants improved their throughput by 20%. Yet, many still hesitate, often questioning the necessity of such upgrades. Investing in quality valves is crucial as it leads to more reliable processes and increased productivity.

Improved Efficiency and Performance in Industrial Systems

Engineered valves play a crucial role in enhancing efficiency and performance in various industrial systems. These valves are designed to withstand extreme conditions while ensuring precise control over flow rates and pressures. They reduce energy consumption by optimizing fluid dynamics, leading to lower operational costs. Additionally, the durability of engineered valves minimizes maintenance demands, allowing for seamless operations without frequent disruptions.

Tip: Regularly inspect your valves to ensure they function optimally. Look for signs of wear or corrosion which can affect performance.

The advanced materials used in engineered valves contribute to their reliability. They can handle corrosive substances and extreme temperatures better than traditional valves. This resilience means fewer replacements and less downtime for companies. However, it’s essential to consider the specific needs of your application when selecting valves. Misalignment in choice can lead to inefficient operations.

Tip: Consult with engineers to determine the best valve type for your system. This step can prevent costly mistakes.

Overall, the integration of engineered valves results in a streamlined process, enhancing productivity. However, ongoing assessments are necessary to adapt systems to evolving needs. Invest time in training your personnel to handle these innovations effectively.

Top 10 Benefits of Engineered Valves in Industrial Applications

This bar chart illustrates the top 10 benefits of engineered valves in industrial applications, highlighting their significant contribution to efficiency, safety, and overall performance within industrial systems.

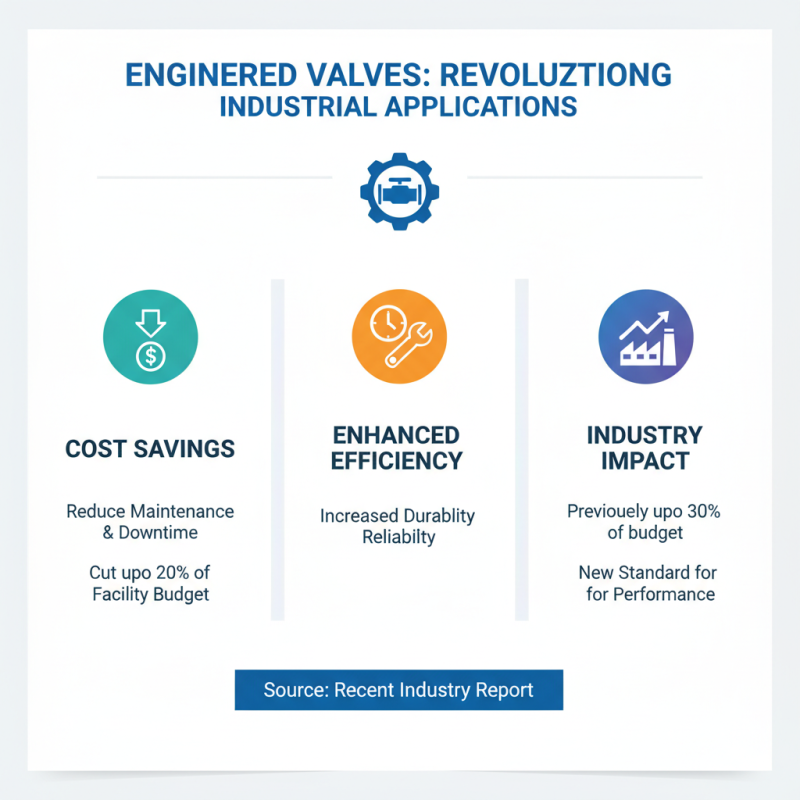

Cost Savings Through Reduced Maintenance and Downtime

Engineered valves are revolutionizing industrial applications. They offer significant cost savings by reducing maintenance and downtime. According to a recent industry report, maintenance costs can account for up to 30% of a facility's budget. By implementing engineered valves, companies can cut these costs by as much as 20%. This efficiency stems from their enhanced durability and reliability.

Many industrial sectors face regular downtime due to valve failures. Reports show that unplanned downtime can cost industries upward of $1 million per hour. Engineered valves minimize this risk. Their precision engineering leads to fewer leaks and failures. This translates into smoother operations and better productivity.

However, not all engineered valves are created equal. Some may still face challenges under extreme conditions. Issues such as material fatigue or sealing problems can arise, requiring attention. Facilities must assess the suitability of these valves for specific applications. Continuous monitoring is essential. It ensures that the benefits of reduced maintenance and downtime are fully realized. Investing in technology is only effective when paired with proactive management strategies.

Versatility of Engineered Valves in Various Applications

Engineered valves play a crucial role in various industrial applications. Their versatility is evident across sectors like oil and gas, water treatment, and pharmaceuticals. According to a recent market research report from Allied Market Research, the global engineered valve market is projected to reach $76 billion by 2027. This data highlights the growing recognition of engineered valves for their adaptability.

In the oil and gas sector, engineered valves manage high pressures and extreme temperatures. They help to prevent leaks, ensuring safety and efficiency. The demand for reliable valves is rising. Key players in the industry report that failures in traditional valves can lead to catastrophic failures. This raises concerns about safety protocols. On the other hand, engineered valves can self-adjust, optimizing workflows and reducing downtime.

Additionally, engineered valves are crucial in water treatment plants. They regulate flow and minimize waste. Studies show that using advanced valve systems can improve treatment efficiency by up to 30%. However, not all facilities implement these technologies. Cost remains a barrier for some organizations. They need to weigh initial investment against long-term benefits. The need for better education on these advantages is essential for industry-wide adoption.

Advanced Technology and Innovation in Valve Design

Engineered valves have transformed industrial applications with advanced technology. Their design emphasizes performance and reliability. These valves incorporate cutting-edge materials that resist corrosion, which extends their service life. Precision manufacturing techniques ensure tight tolerances. Such innovations enhance efficiency and reduce waste in systems.

Increased automation is another hallmark of modern valve technology. Smart valves can now communicate with control systems in real-time. This connectivity allows for precise adjustments that optimize operations. However, this complexity can lead to challenges. Maintenance becomes more complicated, and operators need training to manage these systems effectively.

Listening to operators' feedback is crucial. They often identify practical issues that engineers might overlook. For example, a minor design flaw can complicate installation. Continuous innovation should address these real-world challenges. Balancing advanced features with simplicity could improve usability. Keeping user experience in focus is vital for future developments.

Top 10 Benefits of Engineered Valves in Industrial Applications

| Benefit | Description | Application |

|---|---|---|

| Improved Reliability | Engineered valves provide consistent performance and reduce failure rates. | Oil and Gas Industry |

| Enhanced Safety | Designed to withstand extreme conditions, minimizing leak risks. | Chemical Manufacturing |

| Energy Efficiency | Optimized flow reduces energy consumption in operations. | Power Generation |

| Cost Savings | Longer lifespan leads to lower maintenance and replacement costs. | Manufacturing Facilities |

| Versatility | Applicable in various industries, adaptable to multiple fluids. | Pharmaceuticals |

| Environmental Compliance | Designed to meet environmental standards, reducing emissions. | Waste Water Treatment |

| Automation Capable | Compatible with automated systems for better process control. | Industrial Automation |

| Precision Control | Allows accurate control over fluid flow rates and pressures. | Food and Beverage Processing |

| Reduced Downtime | Long-lasting performance minimizes the need for shutdowns. | Mining |

| Advanced Materials | Constructed using innovative materials that resist wear and corrosion. | Marine Applications |

Related Posts

-

Top Benefits of Engineered Valves for Industrial Applications

-

2025 Top Valve Applications You Need to Know for Future Innovations

-

Understanding the Role of Guide Valves in Modern Hydraulic Systems

-

Understanding Guide Valves: Their Role in Fluid Dynamics with 2023 Industry Insights

-

Top Insights on Through Valve Technology for 2025 and Beyond

-

10 Best Valve Applications for Efficient Industrial Processes

(780) 669-9420

(780) 669-9420