Blog

- Home

- Blog

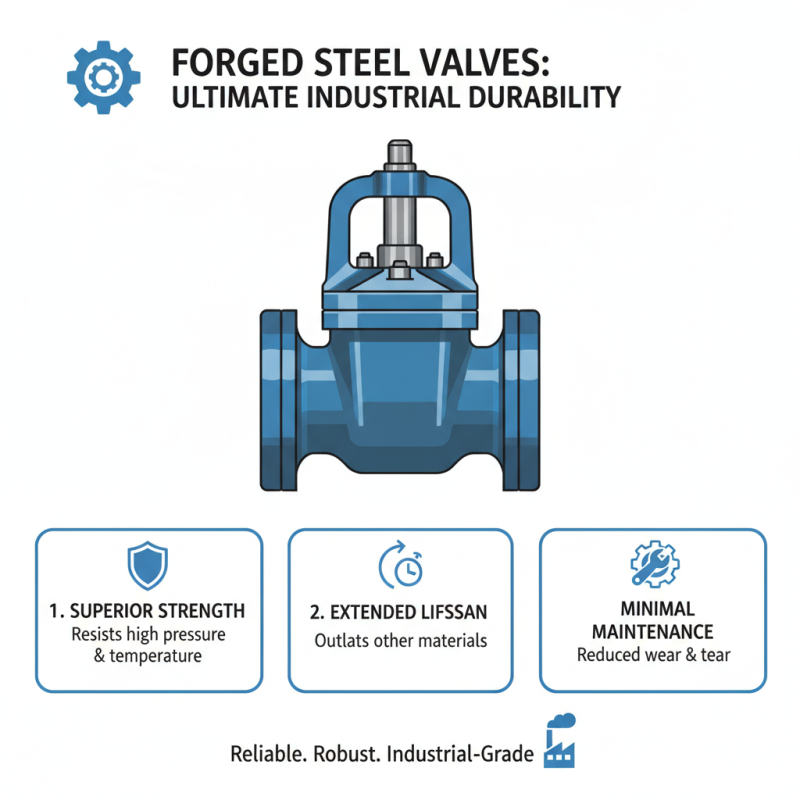

Why Choose Forged Steel Valves for Your Industrial Applications?

Forged steel valves are essential in various industrial applications. They are known for their durability and strength. These valves withstand high pressure and extreme temperatures. Made from robust steel, they outperform many alternatives.

In industries like oil and gas, forged steel valves play a significant role. They ensure the safe and efficient flow of fluids. Their resistance to corrosion and wear enhances their lifespan. However, users must select the right type for specific needs. Not every forged steel valve suits every application.

Consider the cost-benefit of using forged steel valves. They may seem expensive, but their long-term efficiency can save money. Careful evaluation and planning are crucial. Mistakes in choosing the right valve can lead to costly repairs. Understanding the requirements of your system will lead to better choices.

Overview of Forged Steel Valves in Industrial Applications

Forged steel valves are increasingly popular in industrial applications due to their durability and reliability. These valves are made from solid steel, which provides superior strength compared to cast valves. According to industry reports, forged steel can withstand higher temperatures and pressures. This makes them ideal for oil and gas, power generation, and chemical processing industries.

In the oil and gas sector, a study indicated that nearly 80% of facilities prefer forged steel valves. They offer excellent resistance to corrosion and wear. This reduces maintenance costs and downtime significantly. Some reports suggest that using forged valves can lower operation costs by up to 15%. However, not all applications will benefit equally. There can be instances where the initial cost may not justify the long-term savings.

The design of forged steel valves allows for precision and control. Many industrial companies struggle with valve selection due to varying specifications. This can lead to inefficiencies in processes. Proper training and familiarity with forged steel properties are crucial. Lack of knowledge may lead to suboptimal choices, impacting overall operational efficiency. Additionally, while the advantages are clear, the transition from older valve types can be complex.

Why Choose Forged Steel Valves for Your Industrial Applications?

| Dimension | Description | Benefits | Applications |

|---|---|---|---|

| Material Strength | Forged steel offers superior strength compared to cast steel. | High durability and resistance to wear. | Oil & Gas, Petrochemical |

| Pressure Resistance | Designed to withstand high pressure environments. | Ensures system integrity under pressure. | Pipelines, Power Generation |

| Temperature Range | Capable of functioning in extreme temperatures. | Versatile for various industrial processes. | Chemical Manufacturing, HVAC |

| Corrosion Resistance | Plasticity and coating options enhance resistance. | Longer lifespan in corrosive environments. | Marine, Water Treatment |

| Customizability | Can be manufactured to specific needs. | Tailored for specific applications. | Industrial Automation, Mining |

Key Benefits of Using Forged Steel Valves

Forged steel valves are becoming the go-to choice for various industrial applications. One reason is their strength. According to industry reports, forged steel boasts a tensile strength of around 50,000 psi, significantly higher than cast steel. This means they can better withstand high pressures and temperatures. In high-performance settings, this can translate to fewer failures over time.

Another benefit lies in their exceptional durability. Studies indicate that forged steel valves have a longer lifecycle than traditional cast options. They resist wear and corrosion, leading to reduced maintenance costs. This is especially crucial in industries like oil and gas, where valve failure can lead to catastrophic results. In fact, the National Association of Corrosion Engineers estimates that corrosion costs the U.S. economy over $276 billion annually. Choosing forged steel valves can help mitigate this risk.

Yet, challenges remain. Not all manufacturers have access to the same quality materials. Poor quality can lead to inconsistent performance. In critical applications, this can be a matter of safety. It's essential to choose suppliers with a proven track record. High-quality forged steel valves can be more expensive initially, but their long-term savings should not be overlooked.

Comparison of Forged Steel Valves with Other Valve Types

When choosing valves for industrial applications, forged steel valves often stand out. They hold several advantages over other types. Reports indicate that forged steel provides superior strength and durability, making them ideal for high-pressure environments. The tensile strength of forged steel can reach up to 110,000 psi, which significantly outperforms cast iron valves, often averaging around 40,000 psi.

In contrast, plastic or PVC valves may excel in corrosion resistance but can fail under high temperature or pressure. Data suggests that this limits their applicability in high-demand environments. While they are lightweight, the potential for leaks increases. Additionally, they typically have a shorter lifespan, making them less economical over time.

Moreover, forged steel valves are often more reliable in extreme conditions. They exhibit excellent fatigue resistance, reducing the risk of valve failure. However, they can be more challenging to install due to their heavy weight. Installing them may require specialized equipment. This aspect can lead to higher initial installation costs. Nevertheless, the long-term benefits often outweigh these concerns.

Common Applications and Industries for Forged Steel Valves

Forged steel valves are widely used across various industries due to their strength and reliability. In power generation, these valves control the flow of steam and water. They withstand high pressures, ensuring safe operations. In oil and gas, they manage the flow of crude oil and natural gas. Their durability is crucial in preventing leaks and failures.

Chemical processing is another key area. Forged steel valves handle aggressive substances. They resist corrosion, increasing their longevity. Water treatment facilities also utilize these valves. They play a critical role in controlling water flow and maintaining quality. However, improper selection can lead to issues.

Manufacturing processes often depend on these valves, too. They ensure precision and efficiency. Forged steel valves bring stability to dynamic systems. Yet, it's essential to evaluate specific needs before choosing them. Not every application is ideal for forged steel. Understanding the environment helps in making the right decision.

Maintenance and Longevity of Forged Steel Valves

Forged steel valves are known for their durability and strength, making them a preferred choice in various industrial applications. When considering maintenance, these valves can significantly outlast other materials. Their robust structure minimizes wear and tear over time.

Regular inspections are essential for maintaining forged steel valves. Check for signs of corrosion and leaks regularly. Keeping the valves clean can also prevent build-up, which affects performance. Over time, even the best materials can wear down. It’s crucial to remain vigilant.

Tip: Schedule maintenance checks every six months. This can extend the lifespan of your valves.

In harsh environments, forged steel valves perform better than others. However, they are not immune to failure. Environmental factors like temperature and pressure can impact their longevity. Awareness of these factors can help in planning maintenance effectively.

Tip: Document any irregularities you notice. This can provide valuable insight during inspections.

Related Posts

-

Why Forged Steel Valves Are Essential for Industrial Applications

-

Top 10 Benefits of Cast Steel Valves for Industrial Applications

-

Top 10 Benefits of Using DHV Gate Valve in Industrial Applications?

-

Exploring the Future: Top Valve Engineering Innovations of 2025

-

Understanding the Role of Guide Valves in Modern Hydraulic Systems

-

2025 Top Valve Applications You Need to Know for Future Innovations

(780) 669-9420

(780) 669-9420