Blog

- Home

- Blog

10 Essential Tips for Maintaining Your Working Valve Efficiency?

In industrial applications, the efficiency of a working valve plays a crucial role in overall system performance. A recent report from the Valve Manufacturers Association highlights that proper maintenance can improve valve efficiency by up to 25%. This figure showcases the importance of maintaining working valves in various processes, from petrochemical plants to water treatment facilities.

Dr. Emily Reynolds, a notable expert in fluid control systems, states, "Neglecting working valves can lead to inefficiencies that ripple through entire operations." This insight emphasizes the need for proactive approaches to valve maintenance. Factors like wear and tear or improper installation can cause significant setbacks.

Many facilities overlook minor valve issues. Unfortunately, this negligence can lead to costly downtime and inefficient performance. Regular checks and timely interventions are necessary. Industry data indicates that scheduled maintenance leads to fewer unexpected failures and a longer lifespan for working valves. Striking a balance between efficiency and maintenance is key to operational success.

Understanding Valve Types and Their Applications in Industry

Valves are crucial in many industrial applications. They control the flow of fluids and gases. Different types of valves serve different purposes. Gate valves are often used for on-off control. They seal tightly, which minimizes leakages. However, they are not ideal for throttling flow due to pressure drop issues.

Ball valves, on the other hand, offer quick shut-off capabilities. They are excellent for systems requiring frequent cycling. Yet, improper handling can lead to wear and decreased efficiency. Another important type is the globe valve. These are great for regulating flow but can cause significant pressure loss when fully opened. Knowing which valve to use is essential for maintaining efficiency.

Regular maintenance is vital for optimizing valve functions. Over time, wear and tear can affect performance. Not all users recognize signs of valve problems. Checking for leaks or irregular sounds can help. Ignoring these issues may lead to costly downtimes. Each valve type requires tailored maintenance strategies. Understanding these nuances is key to effective operation in any industrial setting.

10 Essential Tips for Maintaining Your Working Valve Efficiency

This bar chart represents the efficiency factors of different valve types commonly used in various industries. Effective maintenance practices can significantly enhance the performance of each valve type. The categories displayed include Gate Valve, Globe Valve, Ball Valve, Butterfly Valve, and Check Valve, with their respective efficiency ratings based on maintenance frequency and application environment.

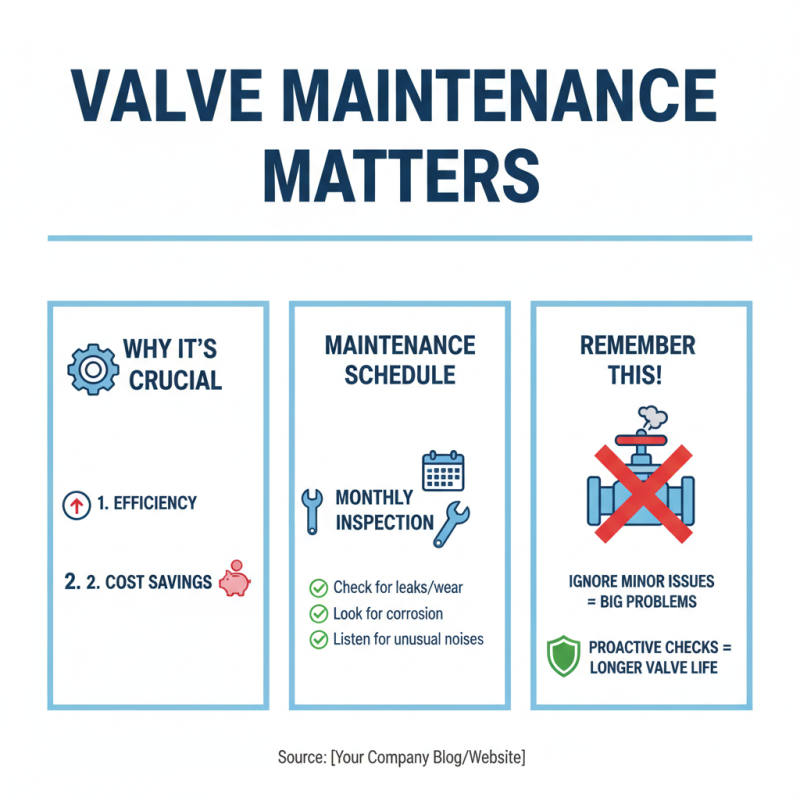

Regular Maintenance Schedule: Best Practices for Longevity

A regular maintenance schedule is crucial for ensuring the efficiency of your working valves. At least once a month, inspect your valves for leaks or wear. Pay attention to signs of corrosion or unusual noises. A quick visual check can save time and costs in the long run. Remember, if you ignore minor issues, they can turn into significant problems.

Consider establishing a detailed maintenance log. Document each check and any repairs made. This record helps identify patterns over time. Are certain valves wearing out quicker? This could indicate an underlying problem. Set maintenance reminders to ensure you never miss a check.

Don’t forget the environment around your valves. Dust, moisture, and temperature swings can affect performance. Sometimes, even a small change in the surrounding can lead to inefficiency. It’s essential to assess not only the valves but also their operating environment regularly. Seek areas for improvement and learn from past oversights. Regular maintenance is an opportunity for reflection on your entire system’s performance.

Evaluating and Measuring Valve Performance Metrics

Evaluating and measuring valve performance metrics is vital for optimizing efficiency in industrial applications. Key performance indicators (KPIs) include leakage rates, response time, and energy consumption. According to industry reports, 20-30% of valve failures result from poor measurements of these metrics. Regular monitoring can prevent failures and enhance overall system performance.

One tip for improvement involves setting clear performance benchmarks. Regular assessments against these benchmarks can illuminate discrepancies. Another important point is to maintain accurate records of valve performance metrics. Tracking these metrics over time can reveal patterns and help you identify areas that need attention.

Measuring valve efficiency should not be a one-time effort. Ongoing evaluations lead to better insights. Sometimes, valves can appear efficient but have hidden issues. Understanding how to interpret performance data is crucial. Analyzing trends can uncover inefficiencies that are not immediately apparent. Regular maintenance based on these evaluations can save time and resources in the long run. Always consider the balance between innovation and maintenance costs in your assessments.

10 Essential Tips for Maintaining Your Working Valve Efficiency - Evaluating and Measuring Valve Performance Metrics

| Tip No. | Maintenance Tip | Frequency | Performance Metric | Target Value |

|---|---|---|---|---|

| 1 | Regular Inspections | Monthly | Leak Rate | < 0.05% |

| 2 | Lubrication | Quarterly | Operating Torque | < 15 Nm |

| 3 | Sealing Surface Inspection | Bi-Annual | Seal Integrity | 100% Integrity |

| 4 | Actuator Performance Check | Monthly | Response Time | < 2 Seconds |

| 5 | Clean Valve Body | Annually | Fluid Flow Rate | Max 250 L/min |

| 6 | Replace Worn Components | As Needed | Wear Rate | < 5% per Year |

| 7 | Monitor Temperature | Daily | Operating Temperature | < 80°C |

| 8 | Calibrate Position Sensors | Semi-Annual | Position Accuracy | ± 1 mm |

| 9 | Inspect Gaskets and Seals | Quarterly | Seal Performance | No Leakage |

| 10 | Train Staff Regularly | Annually | Knowledge Proficiency | > 90% |

Common Causes of Valve Efficiency Loss and How to Prevent Them

Valve efficiency can degrade over time due to various factors. Common causes include wear and tear, corrosion, and improper application. According to industry reports, about 30% of valve failures occur due to inadequate maintenance practices. Regular inspections can prevent these issues. However, many facilities overlook this critical step.

Corrosion is another leading cause of efficiency loss. It can reduce the flow area within the valve. Studies show that about 20% of valves installed experience significant corrosion. Using appropriate protective coatings and monitoring for signs of corrosion can help extend valve life. In many cases, facility teams fail to implement these protective measures.

Additionally, improper installation plays a crucial role in valve performance. Misalignment can lead to leaks and malfunctions. A substantial portion of valve issues, about 25%, stem from installation errors. Training staff on proper installation techniques can mitigate this risk. Routine checks for alignment and seal integrity are essential, yet often neglected. Addressing these issues can lead to improved valve efficiency and reduced downtime.

The Role of Automation and Technology in Valve Management Strategies

In today's fast-paced industrial landscape, automation and technology play pivotal roles in valve management strategies. According to a report by McKinsey & Company, automation can enhance operational efficiency by up to 30%. This highlights the potential of integrating smart technologies in valve maintenance. Sensors and IoT devices can monitor valve performance in real-time, reducing unexpected failures.

Data shows that predictive maintenance, powered by artificial intelligence, can decrease maintenance costs by 25%. It allows companies to act before issues escalate. However, the integration of these technologies isn't always seamless. Organizations often struggle with data overload and system compatibility. The challenge lies in filtering relevant information while ensuring that the technologies work in harmony.

Moreover, a recent study from the International Society of Automation indicates that while most companies understand the benefits of automation, only 40% have fully integrated it into their valve management processes. Some processes remain manual, revealing a gap between recognition and implementation. It's clear that adopting these advancements demands reflection and adaptation, not just investment.

Related Posts

-

2025 Top Valve Applications for Innovative Industries and Effective Solutions

-

Understanding Guide Valves: Their Role in Fluid Dynamics with 2023 Industry Insights

-

Top Benefits of Engineered Valves for Industrial Applications

-

10 Best Valve Applications for Efficient Industrial Processes

-

Top Working Valve Technologies to Watch in 2026

-

Top 10 Benefits of Engineered Valves in Industrial Applications?

(780) 669-9420

(780) 669-9420