Blog

- Home

- Blog

Why Forged Steel Valves Are Essential for Industrial Applications

In the realm of industrial applications, the choice of materials and components can significantly impact efficiency, safety, and durability. Among the various options available, forged steel valves stand out as essential components in numerous systems. Their robust construction and superior strength make them ideal for high-pressure and high-temperature environments, where reliability is paramount. This article delves into the key advantages of forged steel valves, exploring their unique properties, manufacturing processes, and the diverse applications across multiple industries.

The process of forging steel not only enhances the mechanical properties of the material but also ensures a uniform grain structure, which contributes to improved performance and longevity. As industries strive to optimize their operations, understanding the significance of forged steel valves becomes crucial. This discussion will guide readers through the various scenarios in which these valves excel, emphasizing their role in enhancing system integrity and operational efficiency. By examining the benefits and application methods of forged steel valves, we equip industrial professionals with the knowledge needed to make informed decisions, ultimately leading to safer and more efficient processes.

Importance of Forged Steel Valves in Industrial Settings

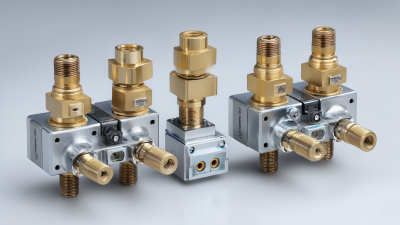

Forged steel valves play a crucial role in various industrial applications, offering a blend of strength and reliability that is essential for efficient operations. Their construction involves the forging process, which enhances the mechanical properties of the steel, resulting in valves that can withstand high pressures and extreme temperatures. This durability is particularly important in sectors such as oil and gas, petrochemicals, and water treatment, where the reliability of valves can greatly influence overall system performance and safety.

In industrial settings, where fluid control and material handling are paramount, forged steel valves provide the precision and durability needed to manage complex processes. Their resistance to corrosion and wear makes them ideal for handling aggressive fluids and gases, thus minimizing maintenance costs and downtime. Additionally, these valves ensure tight sealing, preventing leaks that could lead to safety hazards or operational inefficiencies. As industries continue to demand higher performance standards, the importance of forged steel valves in maintaining safety, efficiency, and operational integrity cannot be overstated.

Key Benefits of Forged Steel Valves Over Other Materials

Forged steel valves have become a cornerstone in various industrial applications due to their unparalleled strength and reliability. One of the key benefits of forged steel valves is their superior resistance to high pressures and temperatures. According to the American Society of Mechanical Engineers (ASME), forged steel exhibits a tensile strength that can exceed 90,000 psi, which makes these valves ideal for high-stress environments such as oil and gas industries. Unlike cast iron or plastic valves, forged steel valves do not easily deform under extreme conditions, ensuring operational safety and longevity.

In addition to their mechanical strength, forged steel valves also benefit from enhanced durability and corrosion resistance. A report by the National Association of Corrosion Engineers (NACE) indicates that industrial sectors can save up to 30% on maintenance costs by utilizing materials that resist corrosion. Forged steel, often treated with specialized coatings, can withstand harsher chemicals and environmental factors, significantly reducing downtime due to maintenance or failure.

**Tips:** When selecting valves for your industrial application, consider those that meet industry standards such as API 602 for forged steel valves. Always ensure compatibility with your system's operating conditions, especially in terms of pressure and temperature ratings, to maximize efficiency and safety.

Why Forged Steel Valves Are Essential for Industrial Applications

| Feature | Forged Steel Valves | Other Materials (Cast Iron, Plastic) |

|---|---|---|

| Strength | Higher tensile strength, suitable for high-pressure applications | Lower tensile strength, may fail under pressure |

| Durability | Long-lasting under harsh conditions | More prone to corrosion and wear |

| Temperature Resistance | Can withstand extreme temperatures | Limited temperature thresholds |

| Repairability | Easily repairable in case of damage | Often requires complete replacement |

| Weight | Generally heavier, providing stability | Lighter, which can reduce support requirements |

| Cost | Higher initial cost, but lower lifetime costs | Lower initial cost, potential for higher maintenance |

Applications of Forged Steel Valves in Various Industries

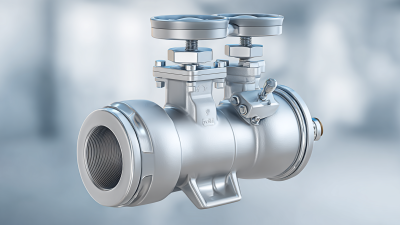

Forged steel valves play a crucial role in various industrial applications due to their superior strength and durability. According to a report by Grand View Research, the global valve market is projected to reach USD 105.04 billion by 2025, with a significant share attributed to forged steel valves. These valves are widely used in the oil and gas sector, where their ability to withstand high pressure and corrosive environments is essential. For instance, the American Petroleum Institute (API) specifies the use of forged steel valves to prevent leaks and ensure safe operations in high-stakes environments.

In water and wastewater management, forged steel valves are critical for maintaining efficiency and safety. A report from Market Research Future indicates that the water treatment valves segment is expected to grow at a CAGR of 6.2% from 2020 to 2027, driven by increasing demand for reliable infrastructure. The robustness of forged steel valves enables them to handle variable flow rates and pressure fluctuations, making them indispensable in treatment plants. Furthermore, in the power generation industry, these valves are used to control steam and cooling water systems, contributing to enhanced operational efficiency and safety standards.

Future Trends and Innovations in Forged Steel Valve Manufacturing

The future of forged steel valve manufacturing is poised for innovation driven by advancements in materials science and technology. As industries push for increased efficiency and reliability, manufacturers are exploring new alloys and heat treatment processes that enhance the performance and longevity of forged steel valves. This evolution not only promises to improve strength and resistance to corrosion but also to accommodate high-pressure and temperature environments, which are increasingly common in sectors such as oil and gas, power generation, and chemical processing.

Moreover, the integration of smart technologies into valve manufacturing is another key trend. Advanced monitoring systems and digital twins are being developed to provide real-time data about valve performance, enabling predictive maintenance and minimizing downtime. These innovations reflect a shift towards Industry 4.0, where automation and data exchange create a more responsive and efficient manufacturing process.

As such, the future landscape of forged steel valve production will likely see a confluence of enhanced material properties and cutting-edge technology, ensuring that these critical components meet the evolving demands of industrial applications.

Selecting the Right Forged Steel Valve for Your Industrial Needs

When selecting the right forged steel valve for industrial applications, several critical factors must be considered to ensure optimal performance and longevity.

Forged steel valves are favored in high-pressure and high-temperature environments due to their superior strength and durability.

According to a report by the National Association of Manufacturers, the demand for forged steel valves is projected to grow at a compound annual growth rate (CAGR) of 7.5% through 2025, driven largely by industries such as oil and gas, power generation, and water treatment.

Understanding the specific requirements of your application is paramount. For instance, the American Society of Mechanical Engineers (ASME) emphasizes the importance of material selection based on the fluid characteristics and operational conditions. Choosing the right valve size, pressure rating, and type—such as gate, globe, or ball valves—can significantly impact efficiency and safety. The wrong choice may lead to failures or inefficiencies, potentially costing businesses thousands in repairs and downtime. Engaging with reputable manufacturers who provide detailed specifications and support can greatly assist in making an informed decision tailored to your industrial needs.

Related Posts

-

Understanding the Role of Guide Valves in Modern Hydraulic Systems

-

Understanding Guide Valves: Their Role in Fluid Dynamics with 2023 Industry Insights

-

Understanding T Valves: The Key Component in Plumbing and HVAC Systems Explained

-

Understanding the Role of Gate Valves in Modern Plumbing Systems

-

Understanding Single Valve Systems: The Key to Efficient Fluid Control in Modern Engineering

-

Exploring the Advantages of Single Valve Systems for Efficient Fluid Control

(780) 669-9420

(780) 669-9420