Blog

- Home

- Blog

Top 10 Guide Valves: Essential Insights and Data for Optimal Performance

In the realm of fluid control, guide valves play a pivotal role in optimizing system performance and ensuring operational efficiency. As industries increasingly rely on precise flow management, understanding the dynamics of guide valves becomes essential. According to a recent report by the Global Valve Market Research Group, the market for guide valves is expected to grow by 6% annually, driven by advancements in technology and an increasing need for energy efficiency in industrial processes. This underscores the significance of selecting the right guide valves for various applications.

Expert insights highlight the impact of valve selection on overall system performance. John Smith, a noted authority in the valve industry, stated, "The right guide valve can significantly reduce energy consumption while enhancing the control of process flows." This sentiment emphasizes the necessity for engineers and procurement professionals to consider not only the functionality but also the long-term benefits of their guide valve choices. As we delve into the top guide valves available in the market today, this guide will provide essential insights and data, equipping readers with the knowledge needed to make informed decisions for optimal performance.

Overview of Guide Valves and Their Applications

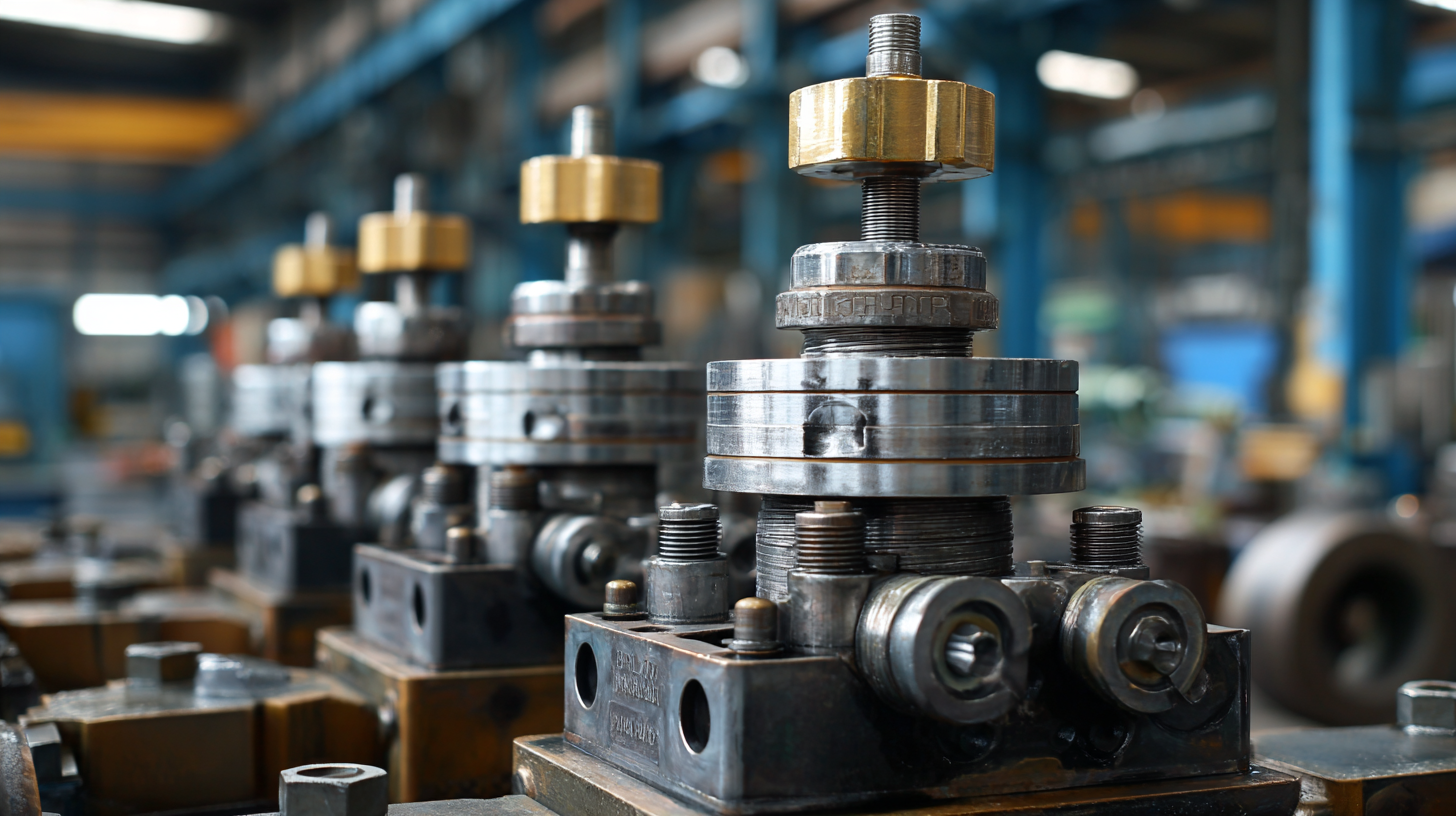

Guide valves play a crucial role in a variety of industrial applications, acting as essential control mechanisms for fluid flow. These valves are specifically designed to direct and regulate the flow of fluids, ensuring optimal system performance. Their structure typically incorporates a guiding element that enhances flow characteristics and minimizes turbulence, which is vital for systems requiring precise control, such as in chemical processing, HVAC systems, and water treatment facilities.

The applications of guide valves extend beyond conventional settings; they are increasingly utilized in ultramodern automation and control systems. In industries such as oil and gas, pharmaceuticals, and food processing, the ability to adjust fluid pathways with precision enables manufacturers to increase efficiency and comply with safety standards. Additionally, advancements in materials and technology have led to the development of smart guide valves, which can automatically adjust based on real-time data, facilitating improved operational performance and reduced energy consumption.

Key Features and Benefits of Different Types of Guide Valves

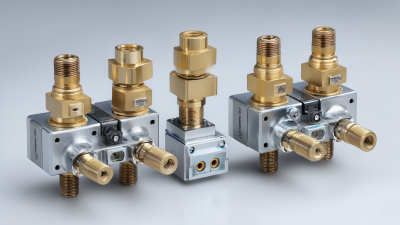

Guide valves play a crucial role in various industrial applications, ensuring controlled fluid flow and enhancing system efficiency. Among the key features that distinguish different types of guide valves are their design, material composition, and mechanism of operation. For instance, globe valves are renowned for their excellent throttling capabilities, making them ideal for applications requiring precise flow regulation. Their ability to withstand high pressures and temperatures further enhances their reliability in critical environments.

Another notable type is the ball valve, which is characterized by its quick opening and closing action, offering excellent sealing capabilities. This type is particularly suited for on/off control and is widely used in oil and gas industries due to its durability. In contrast, butterfly valves are valued for their lightweight design and space-saving attributes, making them an economical choice for large diameter pipes. Each of these valve types not only caters to specific operational needs but also contributes to overall system performance, ensuring optimal fluid management.

Top 10 Guide Valves: Essential Insights and Data for Optimal Performance

| Valve Type | Key Features | Benefits | Common Applications |

|---|---|---|---|

| Globe Valve | Good flow regulation; multi-turn operation | Excellent for throttling; reliable | Water, oil, gas pipelines |

| Gate Valve | Minimal pressure drop; on/off control | Ideal for fully open or closed service | Water supply, wastewater treatment |

| Ball Valve | Quick operation; tight sealing | Durable; allows for quick shutoff | Pipelines, gas lines |

| Butterfly Valve | Lightweight; low pressure drop | Space-saving design; fast operation | HVAC systems, water supply |

| Check Valve | Allows flow in one direction; automatic closure | Prevents backflow; minimal maintenance | Pumps, piping systems |

| Pressure Relief Valve | Automatic pressure release; adjustable | Protects equipment from excess pressure | Boilers, HVAC systems |

| Solenoid Valve | Electromechanical control; fast response | Energy efficient; compact design | Automated systems, irrigation |

| Manual Valve | Human-operated; easy maintenance | Low cost; versatile applications | Oil and gas, water distribution |

| Flow Control Valve | Regulates flow rate; adjustable | Maintains desired flow parameters | Irrigation, industrial systems |

| Pinch Valve | Flexible operation; no contact with media | Suitable for slurries; minimal maintenance | Food processing, wastewater |

Comparative Analysis of Top 10 Guide Valve Brands

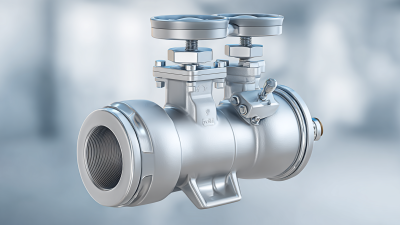

When it comes to selecting the right guide valves for industrial applications, a comparative analysis of leading brands is crucial for optimizing performance. According to a recent report by Frost & Sullivan, the global valve market is projected to grow at a CAGR of 4.2%, driven by the rising demand for efficient flow control solutions. Among the top ten brands, companies like Emerson and Honeywell stand out not only for their advanced technology but also for their commitment to sustainability in manufacturing processes. Emerson’s Fisher brand, for instance, has been recognized for its innovative smart valve positioners that enhance operational efficiency by up to 30% in critical applications.

Another key player, Flowserve, holds a significant market share due to its robust product range and reputation for reliability. A study by MarketsandMarkets indicates that Flowserve's guide valves can handle pressures up to 20,000 psi, making them ideal for high-stakes environments in oil and gas operations. Furthermore, the company’s focus on digital transformation provides clients with real-time monitoring capabilities, propelling maintenance and performance optimization. The comparative insights drawn from these leading brands illustrate not only their technological advancements but also a deeper understanding of market needs, ultimately guiding industries toward making informed decisions in their valve selection processes.

Top 10 Guide Valves Performance Comparison

This chart illustrates the Comparative Analysis of key performance metrics for top guide valve brands. The dimensions represented include Flow Coefficient (Cv), Pressure Drop (ΔP), and Operating Range (OR), showcasing the effectiveness and efficiency of each valve without revealing specific brand names.

Maintenance Tips for Ensuring Optimal Performance of Guide Valves

Guide valves play a crucial role in various industrial applications, and maintaining their optimal performance is essential for efficiency and reliability. Regular maintenance not only extends the lifespan of these valves but also ensures they function correctly. One of the most important maintenance tips is to establish a routine inspection schedule. This includes checking for leaks, ensuring the actuator and valve components are free from debris, and verifying that the valve is opening and closing smoothly.

Another key tip is to regularly lubricate moving parts. Proper lubrication reduces friction, which can lead to wear and tear, ultimately affecting valve performance. It's essential to use the right type of lubricant as specified by the manufacturer to avoid damage. Additionally, monitoring valve performance through data analytics can help identify early signs of wear and potential failures, allowing for timely repairs before they escalate into more significant issues.

Lastly, training staff on proper valve operation and maintenance practices is crucial. Ensuring that all personnel are aware of the correct procedures for handling guide valves can prevent operational errors and promote a culture of safety and efficiency within the workplace. By following these maintenance tips, you can keep your guide valves running optimally and enhance the overall effectiveness of your operations.

Innovations in Guide Valve Technology and Future Trends

Recent innovations in guide valve technology are increasingly shaped by the integration of advanced technologies. For example, AI-powered operational intelligence is revolutionizing water treatment processes by optimizing resource usage and enhancing performance. This shift towards a more sustainable model not only reduces environmental impact but also leads to cost savings in the long run.

The introduction of decentralized infrastructure further supports this trend, allowing for localized solutions that can adapt to specific regional needs and ensure a more reliable water supply.

In the field of interventional cardiology, evolving technologies, such as artificial intelligence-driven diagnostics and 3D echocardiography, are paving the way for personalized treatment approaches. According to current market analyses, the Transcatheter Aortic Valve Replacement sector alone is projected to grow significantly, from $6.5 billion in 2023 to an estimated value of $11.85 billion by 2035. Such growth highlights the emphasis on innovative medical device trends that prioritize patient-centric care while enhancing overall operational efficiency in healthcare environments. As these technologies continue to mature, they hold the promise of not only improving patient outcomes but also streamlining healthcare delivery systems.

Related Posts

-

2025 Top Valve Applications for Innovative Industries and Effective Solutions

-

Understanding Guide Valves: Their Role in Fluid Dynamics with 2023 Industry Insights

-

Understanding the Role of Guide Valves in Modern Hydraulic Systems

-

Why Forged Steel Valves Are Essential for Industrial Applications

-

Understanding the Role of Gate Valves in Modern Plumbing Systems

-

Understanding T Valves: The Key Component in Plumbing and HVAC Systems Explained

(780) 669-9420

(780) 669-9420