Blog

- Home

- Blog

Understanding the Role of Gate Valves in Modern Plumbing Systems

In modern plumbing systems, gate valves play a crucial role in controlling the flow of fluids, ensuring efficient operation and maintenance of water distribution networks. These valves are specifically designed to provide minimal resistance to flow when fully opened, making them ideal for applications that require quick shut-off capabilities. According to industry reports, approximately 25% of all fluid control devices used in commercial plumbing systems are gate valves, highlighting their significant presence in the market. Their ability to handle high pressures and temperatures further solidifies their position as a preferred choice among engineers and plumbing professionals.

The functionality of gate valves extends beyond mere flow control; they are essential in maintaining the integrity and safety of plumbing systems. As reported by the American Society of Plumbing Engineers (ASPE), the proper selection and installation of gate valves can lead to a reduction in maintenance costs by up to 15%, showcasing their economic value in both residential and industrial settings. Furthermore, advancements in materials and design have enhanced their durability and reliability, addressing concerns related to wear and tear in high-demand environments. As plumbing systems continue to evolve, understanding the role of gate valves will be increasingly important for industry stakeholders aiming to optimize system performance and sustainability.

The Importance of Gate Valves in Water Flow Control

Gate valves are essential components in modern plumbing systems, playing a critical role in

water flow control. According to the American Water Works Association (AWWA), gate valves allow for efficient water flow regulation while minimizing pressure loss,

making them invaluable in municipal water distribution networks. Designed for uninterrupted flow, these valves are typically fully open or closed, ensuring that

there is minimal turbulence within the pipeline, which is crucial for maintaining the quality of the water supply.

Gate valves are essential components in modern plumbing systems, playing a critical role in

water flow control. According to the American Water Works Association (AWWA), gate valves allow for efficient water flow regulation while minimizing pressure loss,

making them invaluable in municipal water distribution networks. Designed for uninterrupted flow, these valves are typically fully open or closed, ensuring that

there is minimal turbulence within the pipeline, which is crucial for maintaining the quality of the water supply.

The importance of gate valves extends to their reliability and

longevity in various plumbing applications. A study published in the

Journal of Water Supply Research and Technology highlights that high-quality

gate valves can exceed operational lifespans of 25 years, significantly reducing

maintenance costs and downtime for water systems. Furthermore, their straightforward design allows for easy operation, making them

accessible for routine checks and repairs. As the demand for efficient water management

continues to rise, the role of gate valves in controlling water flow remains paramount in safeguarding infrastructure and ensuring

the delivery of clean water.

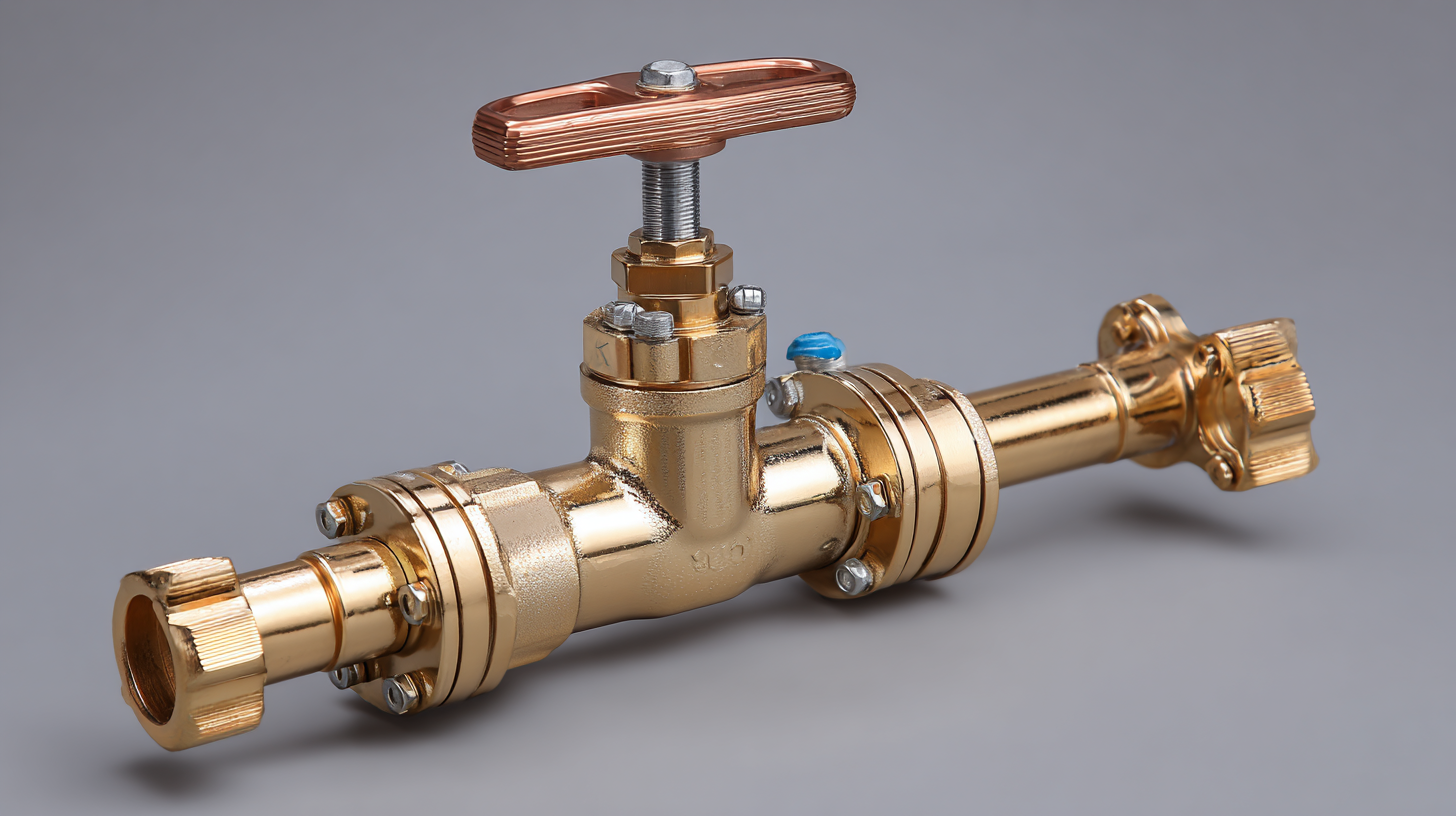

Key Features of Gate Valves: Design and Functionality

Gate valves play a crucial role in modern plumbing systems, providing a reliable means of controlling the flow of liquids and gases. One of their key features is their design, which typically includes a wedge-shaped gate that moves up and down to either allow or restrict flow. According to a recent industry report by Research and Markets, the global gate valve market is projected to grow at a CAGR of 4.5% from 2021 to 2026, driven by the increasing demand for efficient water management and sustainable plumbing solutions.

Another important aspect of gate valves is their functionality. They are designed to minimize pressure loss, allowing for smoother flow, which is essential in large plumbing systems where maintaining pressure is critical. The American Society of Mechanical Engineers (ASME) standards indicate that gate valves can achieve over 90% flow efficiency, making them ideal for applications where high flow rates are required. Furthermore, their ability to provide a tight seal when closed helps prevent leaks, contributing to water conservation and system longevity, which is increasingly important as plumbing regulations become more stringent.

Comparing Gate Valves to Other Valve Types in Plumbing

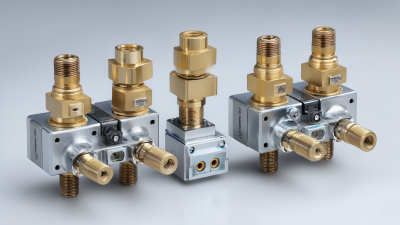

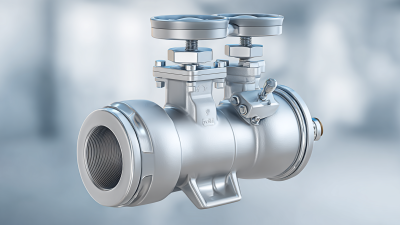

Gate valves are essential components in modern plumbing systems, primarily valued for their ability to provide a straight-line flow with minimal pressure drop when fully open. Unlike other valve types such as globe valves or ball valves, gate valves are designed for isolation rather than throttling. This means that they are ideally suited for applications where the need to stop fluid flow is necessary, allowing for maintenance or repair without disrupting the entire system.

When comparing gate valves to globe and ball valves, one notable distinction is their operating mechanism. Globe valves utilize a disk to throttle flow, making them more suitable for applications requiring flow regulation but less effective in providing full flow capacity. Ball valves, on the other hand, are known for their quick operation and excellent sealing ability, often preferred in situations where a tight shutoff is crucial. However, gate valves shine in large-diameter pipelines where their design allows for efficient flow with less turbulence, making them a reliable choice in scenarios that prioritize uninterrupted fluid movement over adjustable flow control.

Common Applications of Gate Valves in Modern Plumbing Systems

Gate valves are essential components in modern plumbing systems, offering a reliable means of controlling the flow of water and other fluids. These valves are particularly favored for their ability to provide a straight-line flow with minimal pressure drop, making them ideal for applications where uninterrupted flow is crucial. Common applications include main water supply lines, irrigation systems, and fire protection systems. Their design allows for full opening and closing without obstructing the flow, which is critical in instances where large volumes of water need to be quickly controlled.

When selecting gate valves for your plumbing system, consider the material of the valve to ensure compatibility with your system's fluid type and pressure conditions. For example, bronze or stainless steel valves are excellent for high-pressure applications, while PVC valves may suffice for residential water supply systems.

**Tips:** Always size your gate valves appropriately for your piping system to ensure efficiency and avoid unnecessary wear. Regular maintenance and inspection can also prolong the life of your gate valves, ensuring they function effectively when needed.

Understanding the Role of Gate Valves in Modern Plumbing Systems

This chart illustrates the common applications of gate valves in modern plumbing systems, highlighting their significant roles in various sectors including water supply, irrigation systems, fire protection, industrial applications, and wastewater treatment.

Maintenance Tips for Ensuring Optimal Gate Valve Performance

Gate valves are crucial components in modern plumbing systems, providing control over the flow of water and ensuring efficiency in various applications. To keep these valves functioning optimally, regular maintenance is essential. According to a report from the American Society of Mechanical Engineers (ASME), nearly 30% of plumbing system issues stem from valve malfunction, highlighting the importance of proper care.

One vital tip for maintaining gate valves is to exercise them regularly. This means opening and closing the valve at least once every few months, which helps prevent it from seizing up due to mineral buildup or corrosion. Moreover, conducting a visual inspection can reveal any signs of wear or leaks. It is recommended to use a valve lubricant specifically designed for gate valves to ensure smooth operation without compromising the valve's integrity.

Additionally, it is important to monitor water quality, as sediment and mineral deposits can severely impact valve performance. A study from the Plumbing-Heating-Cooling Contractors Association (PHCC) found that valves exposed to hard water conditions may suffer from decreased lifespan and inefficiency. Utilizing water softeners and filters can minimize these effects, thereby enhancing the longevity and reliability of gate valves in plumbing systems.

Understanding the Role of Gate Valves in Modern Plumbing Systems - Maintenance Tips for Ensuring Optimal Gate Valve Performance

| Dimension | Description | Recommended Maintenance Frequency | Signs of Wear | Expected Lifespan |

|---|---|---|---|---|

| Material | Bronze, Stainless Steel, PVC | Every 2-3 years | Corrosion, Cracking | 10-15 years |

| Size | 1/2”, 3/4”, 1”, 2” | On installation | Difficulty opening/closing | 10-20 years |

| Operating Pressure | Up to 300 PSI | Annual inspection | Leaks, Pressure drops | 15-30 years |

| Installation Type | Threaded, Welded, Flanged | Check during plumbing maintenance | Connection loosening | 20-30 years |

Related Posts

-

Understanding Guide Valves: Their Role in Fluid Dynamics with 2023 Industry Insights

-

Understanding the Role of Guide Valves in Modern Hydraulic Systems

-

Exploring the Advantages of Single Valve Systems for Efficient Fluid Control

-

Understanding Single Valve Systems: The Key to Efficient Fluid Control in Modern Engineering

-

Understanding T Valves: The Key Component in Plumbing and HVAC Systems Explained

(780) 669-9420

(780) 669-9420