Blog

- Home

- Blog

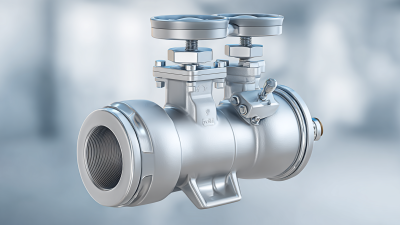

Understanding the Role of Guide Valves in Modern Hydraulic Systems

In the realm of modern hydraulic systems, guide valves serve a critical function that enhances efficiency and precision in fluid control. According to a report by the International Hydraulic Institute, the global hydraulic valve market is projected to reach $16.5 billion by 2026, driven by advancements in automation and the increasing demand for sophisticated hydraulic applications.

Guide valves play a pivotal role in regulating flow directions and maintaining system pressure, which is vital in sectors ranging from industrial manufacturing to aerospace. Furthermore, a recent study indicates that the integration of advanced guide valves can improve system responsiveness by up to 30%, thereby reducing operational costs and increasing productivity. As the demand for efficient hydraulic solutions continues to rise, understanding the mechanics and advantages of guide valves becomes paramount for engineers and industry professionals alike.

The Functionality of Guide Valves in Hydraulic Circuits

Guide valves play a crucial role in the functionality of hydraulic circuits by effectively controlling the flow of hydraulic fluid. These valves serve as directional controls that direct fluid to various components within a hydraulic system, ensuring that actuators operate at the correct times and with optimal efficiency. By opening or closing passages within the circuit, guide valves can regulate pressure and flow rate, thereby enhancing the performance of hydraulic machinery.

In hydraulic applications, the precise control offered by guide valves is essential for achieving the desired movement of hydraulic cylinders and motors. They can be designed to handle specific tasks, such as relieving pressure or switching the flow path based on system demands. By integrating guide valves into a hydraulic circuit, engineers can create systems that respond dynamically to operational needs, improving safety and functionality in industries ranging from manufacturing to automotive. The effective management of hydraulic flow through these valves ultimately results in smoother operation and extended lifespan of system components.

Understanding the Role of Guide Valves in Modern Hydraulic Systems

| Parameter | Description | Importance | Common Applications |

|---|---|---|---|

| Flow Direction Control | Guides the hydraulic fluid flow in desired directions | Ensures system efficiency and prevents backflow | Hydraulic presses, lifts, and shovels |

| Pressure Regulation | Maintains steady pressure levels within the circuit | Protects equipment from pressure spikes | Industrial machinery and automotive applications |

| System Isolation | Isolates sections of the hydraulic circuit for maintenance | Allows safe repairs without shutting down whole system | Construction and heavy equipment |

| Flow Rate Adjustment | Adjusts the speed of hydraulic actuators | Facilitates precise control over movements | Robotics and automation systems |

| Safety Features | Includes mechanisms to prevent accidents | Critical for protecting operators and equipment | Mining and manufacturing industries |

Key Advantages of Implementing Guide Valves in Modern Systems

Guide valves play a crucial role in modern hydraulic systems, offering enhanced control and efficiency. One of the primary advantages of implementing guide valves is their ability to direct fluid flow with precision. This precise control ensures that hydraulic systems operate smoothly, minimizing the risk of fluctuations that can lead to equipment wear and failure. Additionally, by optimizing flow paths, guide valves contribute to energy savings, making hydraulic systems more sustainable.

**Tips:** When integrating guide valves, consider the specific requirements of your hydraulic system. Selecting the right type of valve tailored to your application can significantly enhance system performance. Regular maintenance and inspections of these valves are also essential to ensure their longevity and reliability.

Another key advantage of guide valves is their role in improving system responsiveness. By allowing quick adjustments in flow direction, these valves enable faster actuator movements, which is critical in applications requiring immediate response, such as robotics and automation. This increased speed not only boosts productivity but also helps to maintain safety standards in dynamic environments.

**Tips:** Always monitor the operating conditions of your guide valves. Keeping track of parameters such as pressure and temperature can help in identifying potential issues before they escalate. Consider using digital monitoring solutions to streamline this process.

Understanding the Role of Guide Valves in Modern Hydraulic Systems

This chart illustrates the key advantages of implementing guide valves in modern hydraulic systems, including their impact on efficiency, reliability, and operational costs.

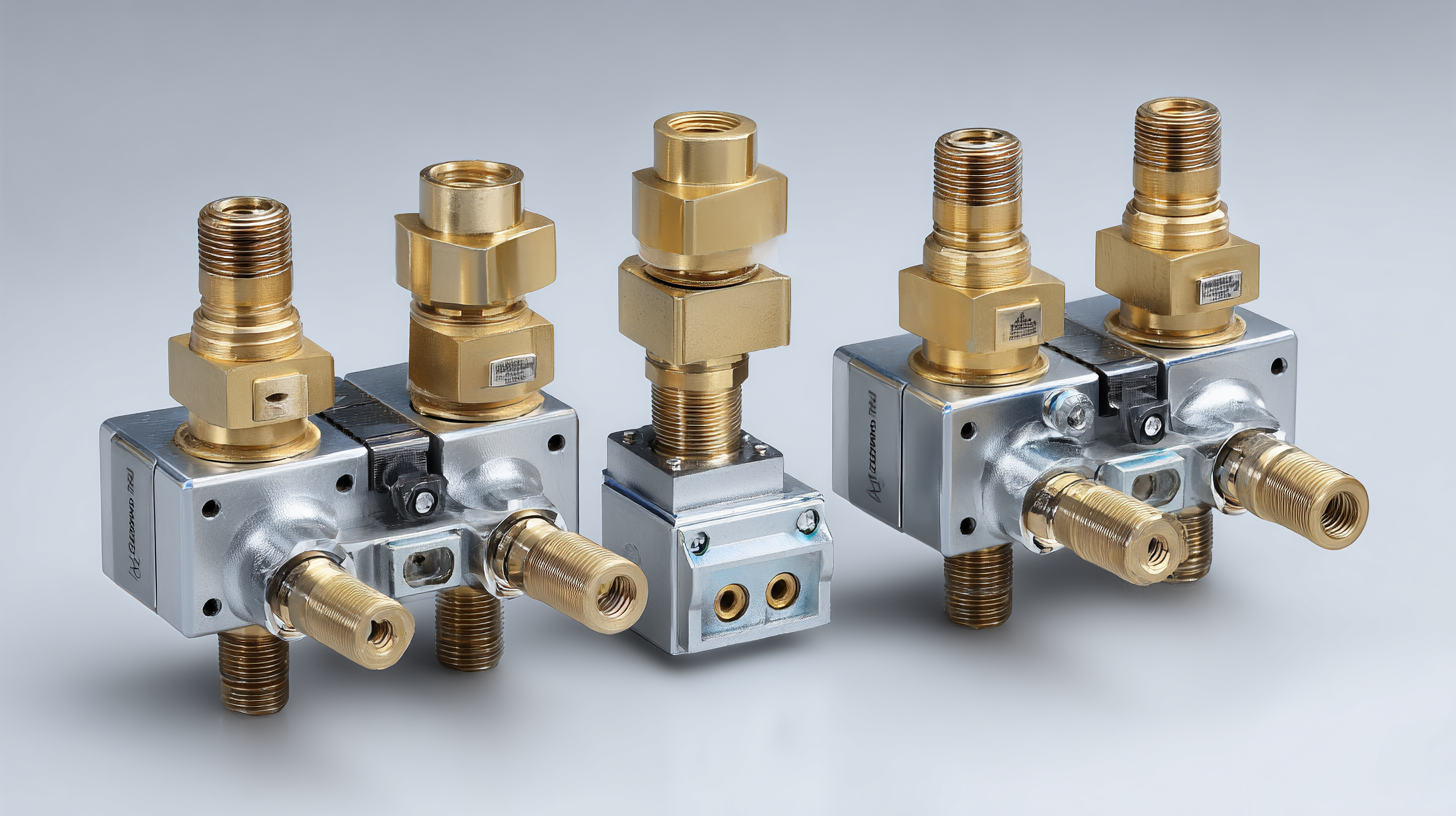

Common Applications of Guide Valves in Various Industries

Guide valves play a significant role in various industrial applications, serving as crucial components in hydraulic systems.

They are widely used for flow control, pressure regulation, and safety in numerous sectors, including oil and gas, chemical processing, pharmaceuticals, and food production.

In hydraulic systems, guide valves help manage the direction and flow rate of fluids, which is essential for maintaining operational efficiency and ensuring the safety of processes.

In the oil and chemical industries, guide valves are particularly vital, as they facilitate the precise handling of aggressive substances and influence overall system performance.

The pharmaceutical sector also benefits from guide valves, where they help maintain sterile conditions and strict compliance with safety regulations. Additionally, in food production, these valves ensure that processing systems operate smoothly while adhering to hygienic standards.

As industries continue to evolve, the demand for reliable guide valves is expected to grow, highlighting their importance in the modernization of hydraulic systems across multiple sectors.

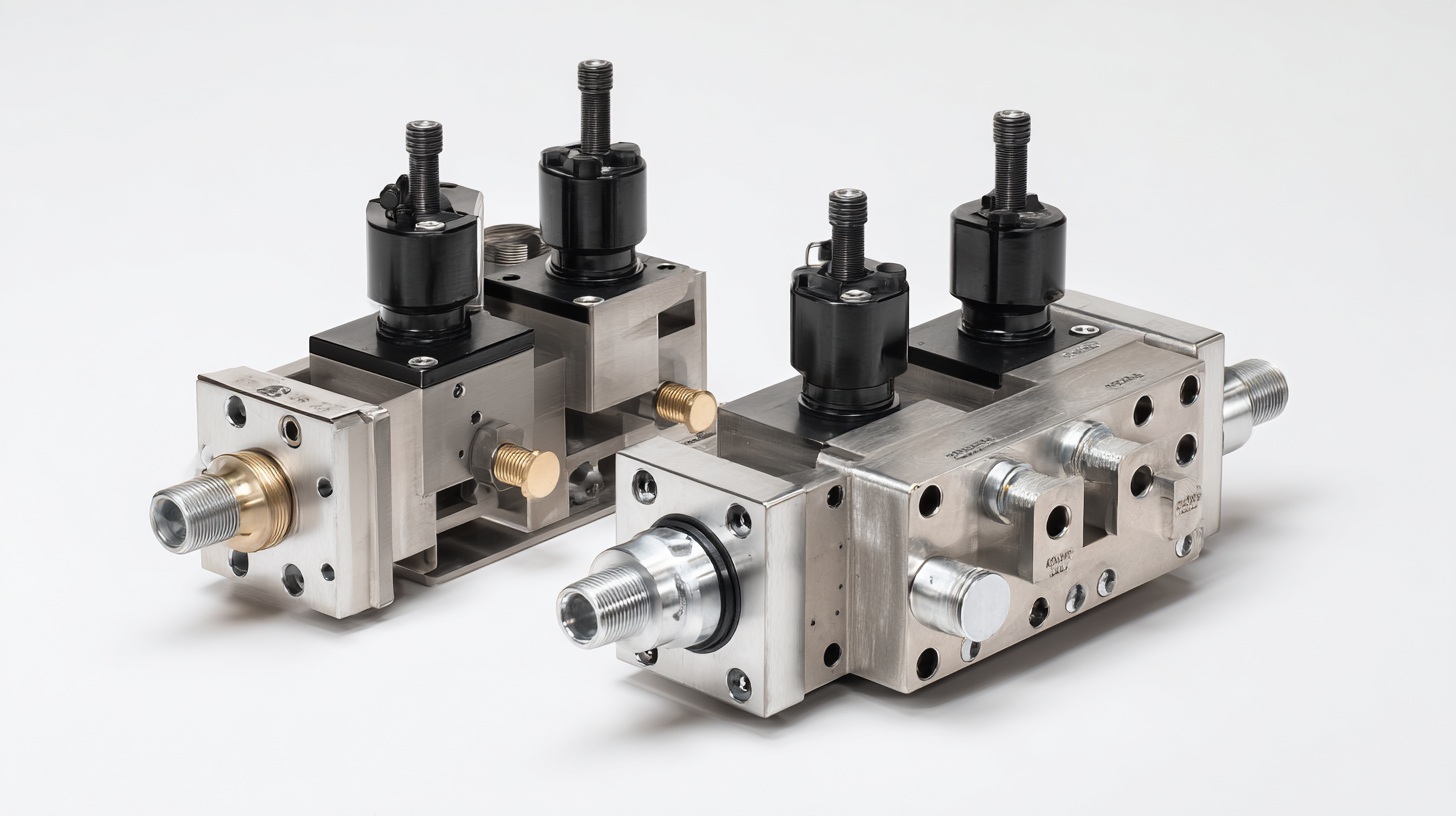

Challenges and Solutions in Using Guide Valves for Hydraulic Control

Guide valves play a pivotal role in modern hydraulic systems, ensuring precision and control in fluid dynamics. However, their integration comes with various challenges. One major issue is the need for reliable operation in demanding environments, where fluctuations in pressure and flow can lead to valve failure. Additionally, the compatibility of materials used for guide valves is critical, especially in chemical and petrochemical applications, where aggressive substances can corrode components, causing delays in operations and increased maintenance costs.

To address these challenges, innovations in valve design and robust materials are being developed. Utilizing advanced engineering techniques and an array of actuator options, modern guide valves can enhance system responsiveness and minimize downtime. Furthermore, the growing adoption of digital technologies allows for real-time monitoring and predictive maintenance, which helps in preemptively identifying potential failures before they disrupt operations. As the hydraulics market continues to expand, stakeholders must remain vigilant about these challenges and actively pursue tailored solutions that boost the efficiency and longevity of guide valves in hydraulic control systems.

Future Innovations and Trends in Guide Valve Technology for Hydraulics

The hydraulic valve market is on the rise, with estimates projecting its size to reach $770 million by 2025 and grow to $1.16 billion by 2033, reflecting a compound annual growth rate of 5.2%. This growth highlights the increasing significance of innovative technologies, particularly guide valves, in modern hydraulic systems. As industries advance, the need for efficiency and reliability in hydraulic applications continues to drive investments in valve technology.

Recent developments in guide valve technology are promising, paving the way for enhanced performance and reduced operational costs. The industry is witnessing a transformation spurred by new brands entering the market and existing companies redefining their identities to stay competitive. For instance, the rebranding of a major hydraulic entity marks a strategic shift aimed at emphasizing modernization and global reach. This not only positions them in a stronger market but also signals a commitment to optimizing hydraulic solutions for various applications.

Tip: When selecting guide valves for hydraulic systems, consider factors such as pressure ratings, materials compatibility, and maintenance requirements to ensure long-term performance and efficiency. Additionally, staying informed about emerging trends in valve technology can help organizations make strategic decisions that align with future market demands.

(780) 669-9420

(780) 669-9420