Blog

- Home

- Blog

Why is a T Valve Essential for Plumbing Systems?

In plumbing systems, the t valve plays a crucial role. It allows the control of water flow in multiple directions. A t valve connects pipes in a compact structure, making it essential for efficient water management.

Many systems rely on t valves but may overlook their importance. Without these valves, plumbing would face major issues. Water could flow unpredictably, leading to leaks or pressure problems.

Sometimes, people might consider alternatives. However, substituting a t valve can create challenges. It can lead to inefficient layouts and potential failures. Recognizing the value of a t valve is vital for any plumbing system's reliability.

The Functionality of T Valves in Plumbing Systems

T valves play a critical role in plumbing systems. They enable the diversion of water flow in various directions. This function is vital for both residential and commercial plumbing. According to industry reports, nearly 70% of plumbing-related issues stem from improper water flow management. This emphasizes the importance of T valves in maintaining system efficiency.

In practical terms, a T valve allows for the branching of water lines. This means water can be directed to multiple fixtures simultaneously, like sinks, showers, or toilets. When a T valve fails, it can lead to uneven water pressure, causing frustration. Observations indicate that a 10% drop in water pressure can occur without proper valve functionality. This can also result in higher utility bills.

The installation of T valves often requires precise measurements. Misjudgment can lead to leaks or bursts. Inadequate installation can diminish the lifespan of the plumbing system. Reports show that nearly 30% of plumbing failures are linked to poor valve choice or placement. It's crucial to approach T valve integration with careful planning and consideration.

Common Applications of T Valves in Residential and Industrial Plumbing

T valves play a crucial role in both residential and industrial plumbing systems. They allow for the control and distribution of water flow. In homes, T valves are often used in heating systems. They help connect radiators to the main water supply, ensuring even heat distribution. The design is simple but effective in directing water where needed.

In industrial settings, T valves are vital in process lines. They help manage different fluid flows, preventing system overloads. For example, a factory might use T valves to divert water to cooling towers or recycling systems. Misplacement of these valves can lead to inefficiencies. Users must regularly check and maintain them.

While T valves seem straightforward, understanding their importance is essential. Improper installation can cause leaks or pressure issues. Homeowners and professionals alike must recognize their role in a well-functioning plumbing system. Knowledge and awareness can prevent future headaches.

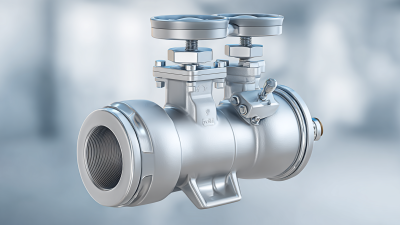

Technical Specifications and Standards for T Valves in Plumbing

T valves play a crucial role in plumbing systems. Their technical specifications are vital for ensuring efficient water flow and pressure management. The American Society of Plumbing Engineers (ASPE) indicates that T valves must withstand high pressures and temperatures. Common materials include brass and stainless steel, which provide durability and resistance to corrosion.

Typically, T valves are rated for pressures between 125 to 250 PSI. They can handle temperatures up to 200°F, depending on the specific application. Proper sizing is essential to avoid flow issues. Misjudged dimensions can lead to reduced performance or system failures. It's critical to follow specifications set by organizations like ASPE and the International Plumbing Code (IPC).

Installation errors can occur without careful adherence to technical standards. An improperly installed T valve may create leaks or pressure fluctuations. The right type must match the plumbing system's requirements. Technical knowledge is necessary for optimal performance. Each scenario requires tailored solutions based on exact requirements. Understanding specifications ensures the longevity of plumbing systems.

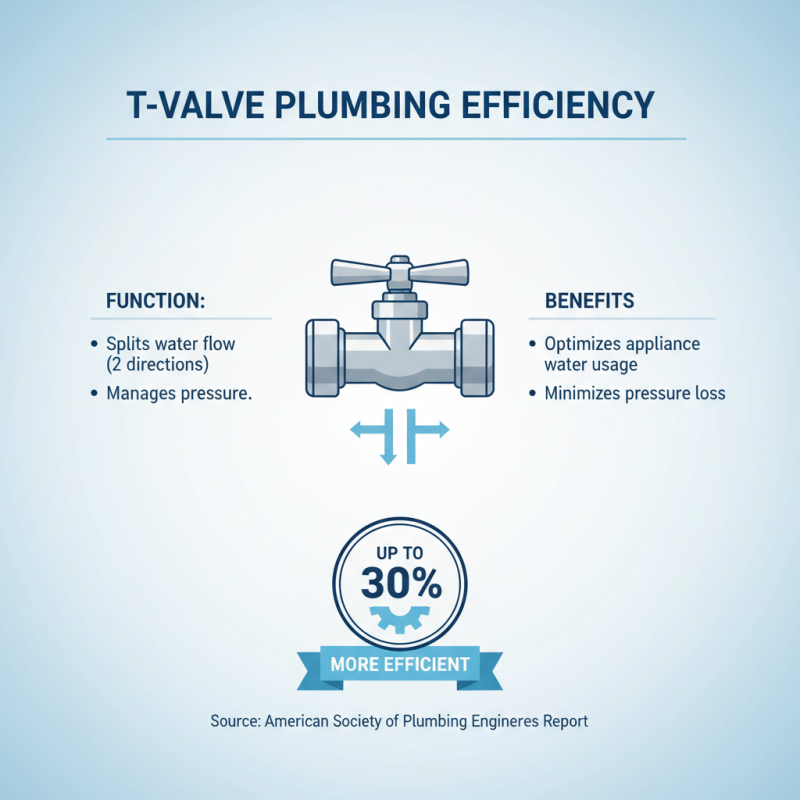

The Impact of T Valves on Water Flow and Pressure Management

T valves play a crucial role in plumbing systems, particularly in managing water flow and pressure. They allow water to split into two directions, optimizing usage across various appliances. According to a report by the American Society of Plumbing Engineers, a well-placed T valve can enhance water distribution efficiency by up to 30%. This efficiency minimizes pressure loss, which is critical for systems serving multiple outlets.

Effective pressure management is also essential. Water systems often experience fluctuations in pressure. A T valve can help stabilize this pressure, ensuring consistent flow. Inconsistent pressure can lead to dysfunctions, like dripping faucets or low flow rates. While some systems manage this well, many fail to account for proper valve placement. A misaligned or poorly installed T valve can worsen pressure issues and lead to costly repairs.

Additionally, regular maintenance of T valves is necessary. Neglect can lead to leaks or blockages, which disrupt water flow. Data indicates that almost 20% of plumbing issues stem from faulty valves. Owners sometimes overlook this point, assuming everything is fine. However, minor inspections can prevent major problems down the line. Regular checks should be part of any plumbing maintenance routine.

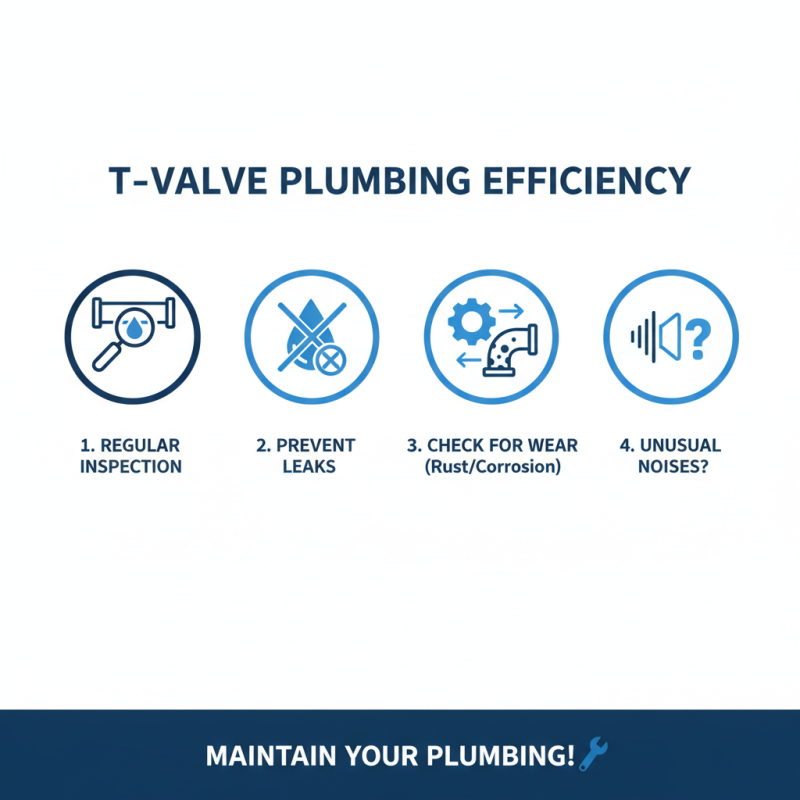

Maintenance Best Practices for Ensuring T Valve Efficiency and Longevity

Maintaining a T valve is crucial for plumbing efficiency. Regular inspection can prevent unexpected leaks. Check for signs of wear, such as rust or corrosion. Take note of unusual noises. These could signal that maintenance is needed.

Tip: Regularly clean the T valve to remove debris. This helps to maintain smooth operation. A simple wipe-down can make a difference. If you notice reduced water flow, it may indicate blockage or buildup inside the valve.

Always ensure that the valve is properly lubricated. Use appropriate grease to avoid seizing. Tighten fittings, but don’t overdo it. Over-tightening can lead to cracks. It’s a delicate balance that requires attention to detail. Reflecting on past issues can guide future maintenance.

Related Posts

-

Understanding T Valves: The Key Component in Plumbing and HVAC Systems Explained

-

Understanding Single Valve Systems: The Key to Efficient Fluid Control in Modern Engineering

-

Top 10 Best Valve Selection Tips for Optimal Performance?

-

Why Choose DHV Gate Valve for Your Industrial Applications

-

Exploring the Advantages of Single Valve Systems for Efficient Fluid Control

-

Top 10 Benefits of Using DHV Gate Valve in Industrial Applications?

(780) 669-9420

(780) 669-9420