Blog

- Home

- Blog

2026 Top Gate Valve Types for Your Industrial Applications?

Gate valves are essential components in various industrial applications. Their primary function is to control fluid flow. In many systems, they are the preferred choice due to their effectiveness and durability. In 2026, several gate valve types will stand out for their unique features.

These valves come in different designs to suit specific needs. Some are made from stainless steel, while others use PVC. Each material has its benefits. For example, stainless steel is resistant to corrosion, making it ideal for harsh environments. PVC, on the other hand, is lightweight and easier to install. Understanding these differences can be crucial.

Yet, selecting the right gate valve is not always straightforward. Misjudgments can lead to inefficiencies or even failures. With evolving technology, new types are emerging that may not be well understood. As industries grow and change, staying informed about these options is vital. Making the right choice now can save time and resources in the future. Exploring the top gate valve types for 2026 will provide the insights needed for effective decision-making.

Overview of Gate Valve Types for Industrial Use

Gate valves are essential in various industrial applications, offering control over fluid flow. They are designed to either allow or block the passage of liquids and gases. In industries like oil, gas, and water treatment, choosing the right gate valve type is critical. Each type has unique features that cater to specific needs.

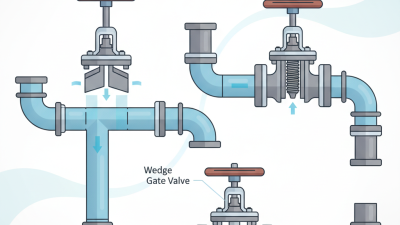

One common type is the solid wedge gate valve. It ensures minimal leakage and can handle high-pressure environments. The flexibility of this design helps in maintaining a tight seal. However, its operation can be slower, which may not suit all scenarios. Another type is the split wedge gate valve. This design allows for easier maintenance and adaptability to fluctuating pressures. Yet, it might require replacing components more frequently.

Moreover, a rising stem gate valve offers clear visual indications of the valve position. Users can quickly assess whether the valve is open or closed. While this feature is beneficial, the rising stem design can be a disadvantage in space-constrained areas. Selecting the right valve type must reflect both operational needs and site-specific limitations. Careful assessment is necessary to avoid costly mistakes.

2026 Top Gate Valve Types for Your Industrial Applications

Key Materials Used in Manufacturing Gate Valves

Gate valves are critical in various industrial applications. The materials used in their construction significantly impact performance and longevity. Common materials include stainless steel, ductile iron, and bronze. Each has unique properties that suit different environments.

Stainless steel is highly resistant to corrosion and high temperatures. This material is ideal for harsh conditions. Ductile iron offers strength and durability. However, it may corrode over time without proper treatment. Bronze, on the other hand, is excellent for marine applications. It can withstand seawater but may not hold up against acidic fluids.

Choosing the right material is complex. Compatibility with the fluid being transported is vital. Factors like temperature and pressure must also be considered. Neglecting any of these aspects can lead to failure. It's essential to evaluate the specific needs before making a decision. Even experienced users sometimes overlook this critical step.

Performance Characteristics of Different Gate Valve Designs

Gate valves are essential in industrial settings, facilitating the control of fluid flow. Different designs of gate valves exhibit unique performance characteristics. For instance, wedge gate valves are popular for their durability. They create a tight seal, effectively preventing leaks. However, they may require more space for operation.

Another design is the rising stem gate valve. This type provides visual indications of valve position. Operators can easily monitor whether the valve is open or closed. Yet, this design can be more complex and might not suit low-clearance environments.

Parallel disc gate valves present a unique option. They feature two parallel discs that provide a more uniform sealing surface. This can enhance reliability but can also lead to challenges in alignment. Each design has advantages and drawbacks. It's vital to consider the specific application needs when selecting a valve type.

Applications of Gate Valves in Various Industries

Gate valves play a crucial role across various industries, ensuring efficient flow control in pipelines. They are predominantly used in water supply plants, oil refineries, and chemical processing facilities. The global gate valve market was valued at approximately $5 billion in 2022 and is projected to grow steadily. In applications involving high pressure and temperature, gate valves excel due to their robust build and reliability.

In the oil and gas sector, these valves are essential for managing the flow of crude oil and natural gas. They ensure a tight seal, minimizing leakage. In water treatment plants, gate valves are used to isolate sections for maintenance without disrupting the overall system. The efficiency these valves bring can lead to reduced operational costs over time.

Tips: When selecting a gate valve, consider the material. Different materials, like stainless steel or bronze, suit specific environments better. Also, assess the valve’s size and pressure rating carefully. These factors can affect performance and longevity significantly. Regular maintenance checks help avoid unexpected failures, which can be costly. Sometimes, overlooked details lead to issues that disrupt operations. Make sure to reflect on past experiences when choosing your valve solutions.

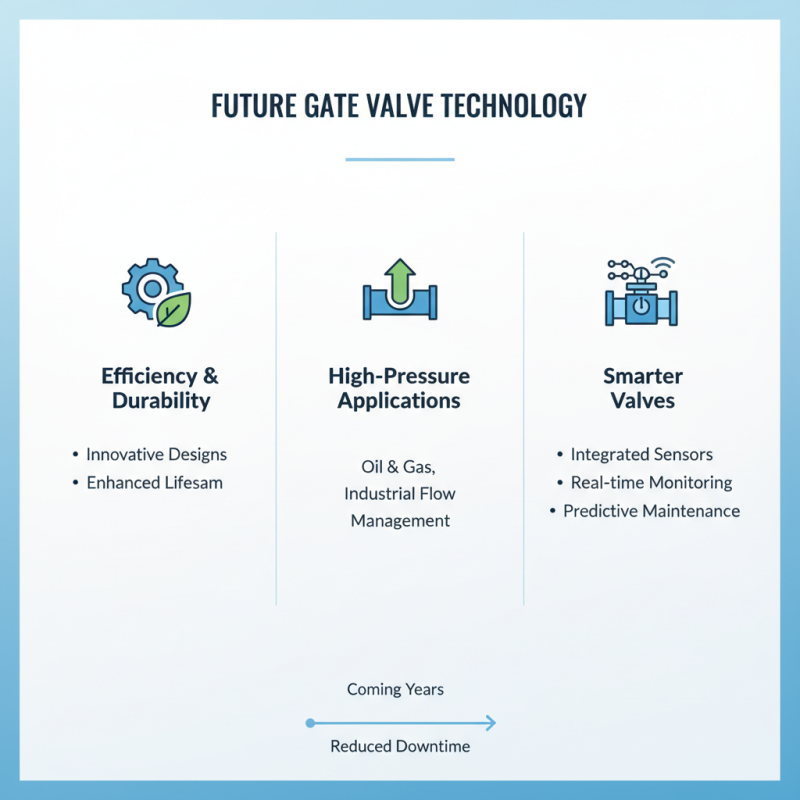

Future Trends in Gate Valve Technology and Innovation

In the coming years, gate valve technology will see notable advancements. Innovative designs will emphasize efficiency and durability. These valves are crucial in industries like oil and gas. They manage high pressure and flow rates. Future trends point towards smarter valves with integrated sensors. These sensors monitor performance in real-time. Such technology can predict maintenance needs, reducing downtime.

New materials will also influence gate valve construction. Lightweight composites may replace traditional metals. This can enhance corrosion resistance. However, the reliability of new materials needs scrutiny. Testing under extreme conditions is essential. Eco-friendliness will be another focus. Manufacturers might explore sustainable production methods. Balancing innovation with proven designs can be challenging. There’s always the risk of unintended consequences in new technology. Understanding these trends can help industries make informed decisions.

Related Posts

-

Why Choose a Gate Valve: Benefits and Applications in Modern Plumbing Systems

-

Top 10 Benefits of Using DHV Gate Valves for Efficient Pipeline Management

-

Why Choose a 4 Gate Valve for Your Industrial Applications?

-

Best Gate Valve Types You Need to Know for Your Plumbing Projects

-

Why Choose DHV Gate Valve for Your Industrial Applications

-

Top 10 Benefits of Using DHV Gate Valve in Industrial Applications?

(780) 669-9420

(780) 669-9420