Blog

- Home

- Blog

Top Working Valve Technologies to Watch in 2026

The landscape of the working valve industry is poised for significant transformation by 2026. With the growing demand for efficient and sustainable solutions, innovative technologies are emerging. According to a recent report by the International Valves Association, the working valve market is expected to grow by 8% annually over the next three years. This is largely attributed to advancements in smart valve technology and automation.

Industry expert Dr. Emily Carter states, "The future of working valves relies heavily on integrating IoT solutions." Her insights highlight the importance of digitalization in valve technologies. Companies are shifting towards automated systems to enhance performance and reduce operational costs. However, the challenge remains in balancing innovation with reliability.

Stakeholders must critically assess emerging trends. While smart valves promise efficiency, there could be unintended complexities in their implementation. This upcoming era in working valve technology demands careful consideration of potential pitfalls. Organizations should strive for transformative design while ensuring maintenance and adaptability. The future of working valves is bright but requires ongoing reflection and strategic foresight.

Emerging Valve Technologies Shaping the Future of Industry in 2026

Valves play a critical role in various industries, ensuring fluid control and efficiency. In 2026, several emerging valve technologies are set to transform industrial processes. Smart valves are gaining traction. They incorporate IoT capabilities, allowing real-time monitoring and data collection. Reports indicate that smart valve adoption could increase by 35% in the next few years. This technology enables predictive maintenance, minimizing downtime and enhancing safety.

Another noteworthy development is the rise of advanced materials in valve production. Materials like carbon nanotubes and composites improve durability and resistance to extreme conditions. Data suggests that these materials can enhance valve lifespan by up to 50%. However, transitioning to these advanced materials presents challenges. Cost and production methods need refinement. Effectively addressing these issues will shape the industry landscape.

Digital twins are also emerging in valve technology. This simulation method allows designers to test valves in virtual environments before physical production. Industry experts predict this could reduce errors by 30%. Despite these advancements, the learning curve remains steep. Industries must invest in training and adaptation. Implementing these technologies could lead to significant shifts in operational efficiency. The path forward is exciting, yet it requires careful navigation.

Key Innovations in Actuator Systems for Enhanced Valve Performance

In 2026, actuator systems are set to undergo significant innovations. These advancements aim to enhance valve performance across multiple sectors. Smart actuators are gaining traction, utilizing sensors and AI to optimize operation. This allows for real-time adjustments based on flow conditions and system demands. Users can expect increased efficiency and reduced downtime.

Wireless technology is emerging in actuator systems. This shift simplifies installation and maintenance, eliminating cumbersome wiring. However, challenges remain with reliability under adverse conditions. Some systems may struggle with connectivity or battery life, requiring careful consideration during deployment. Integrating these technologies demands a balance between innovation and practical deployment.

Improved materials will also play a role. Lightweight and durable composites can enhance actuator longevity. Yet, these materials can have varying performance in extreme environments. Industry professionals must evaluate their choices based on specific applications. This ongoing evolution in actuator design emphasizes the need for continuous improvement and adaptation.

Top Working Valve Technologies to Watch in 2026

Advancements in Materials for Improved Durability and Efficiency

Advancements in materials technology are set to reshape the valve industry by 2026. Engineers are exploring new compounds that promise enhanced durability. These materials aim to withstand extreme conditions better than ever. Innovations in composites and ceramics are leading the way. They resist corrosion and fatigue, making them ideal for demanding applications.

Another key area is reducing weight without sacrificing strength. Lighter valves enhance efficiency in various systems. This could alter how industries approach design and installation. However, achieving this balance is challenging. Some lightweight materials may lack the necessary resilience. Testing and validation remain crucial in these developments.

Sustainability is increasingly important too. Eco-friendly materials are gaining attention. They not only help reduce environmental impact but can also enhance performance. This trend indicates a shift towards greener practices in the industry. Yet, some may question the long-term viability of these alternatives. Ongoing research will be essential to address such concerns. The evolution of valve technologies will be an interesting journey to observe.

Top Working Valve Technologies to Watch in 2026 - Advancements in Materials for Improved Durability and Efficiency

| Technology | Material Used | Durability (Years) | Efficiency (%) | Applications |

|---|---|---|---|---|

| Smart Control Valves | Composite Alloys | 15 | 90 | Oil & Gas, Chemical Processing |

| Corrosion-Resistant Valves | Stainless Steel Coatings | 20 | 85 | Water Treatment, Marine Applications |

| High-Temperature Valves | Ceramic Composites | 25 | 95 | Power Generation, Aerospace |

| Self-Sealing Valves | Reinforced Polymers | 10 | 80 | Pharmaceuticals, Food Processing |

The Role of IoT and Smart Technologies in Valve Automation

The rise of IoT and smart technologies is reshaping valve automation. These advancements enhance efficiency and improve management systems. Sensors connected via IoT enable real-time data collection. This allows for better decision-making based on accurate information.

Regular updates in valve technologies require constant learning. Employees need training to keep pace with innovations. Embracing change is critical, but it can be overwhelming. Tips for this include staying informed through industry publications. Building a network of experts is also essential. Engage in discussions and webinars to expand your knowledge.

Unforeseen challenges can arise. Not all equipment integrates smoothly with new technologies. Plan for potential issues with compatibility. A proactive strategy minimizes disruptions. Keep communication open within teams to address concerns. Smart solutions offer great promise, yet they necessitate careful implementation for success.

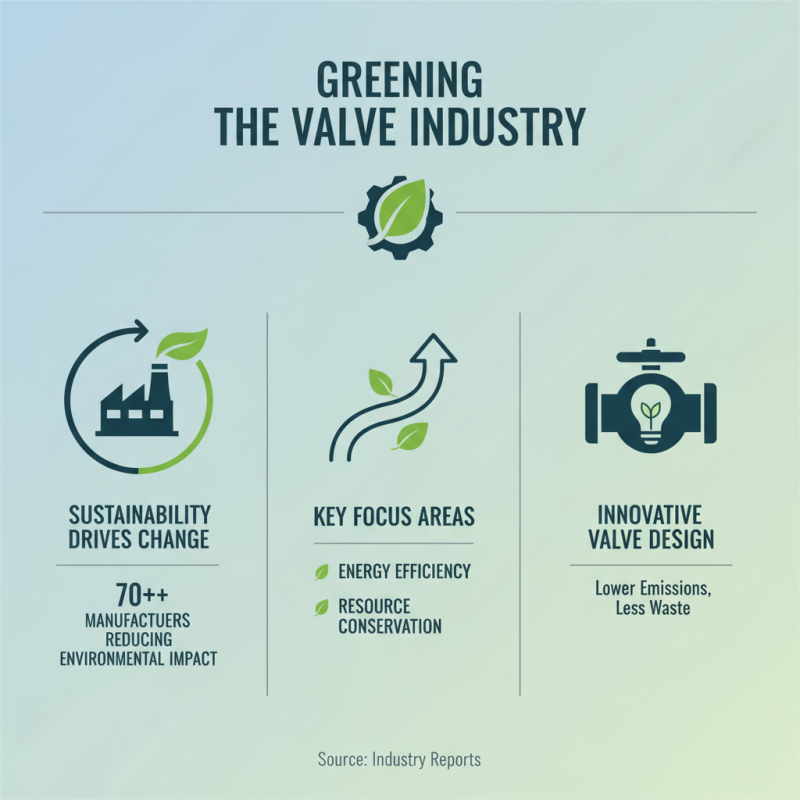

Sustainability Trends Influencing Valve Design and Manufacturing Practices

The valve industry is increasingly influenced by sustainability trends. As per industry reports, over 70% of manufacturers are making changes to minimize their environmental impact. Innovations in valve design now prioritize energy efficiency and resource conservation.

Smart technologies are emerging in valve manufacturing to reduce waste. Manufacturers are adopting materials that are recyclable and have lower carbon footprints. Data shows that valves made with sustainable materials can reduce emissions by up to 35%. This shift not only benefits the planet but can also lead to cost savings in the long run.

Tips: Consider collaboration with suppliers who share sustainability goals. Monitor industry standards for eco-friendly practices. Engage in training programs that emphasize sustainable manufacturing techniques. This approach not only enhances product quality but also builds a responsible brand image.

Related Posts

-

Top Benefits of Engineered Valves for Industrial Applications

-

2025 Top Valve Applications for Innovative Industries and Effective Solutions

-

Top 10 Guide Valves: Essential Insights and Data for Optimal Performance

-

How to Effectively Control Flow Through Valve Systems for Optimal Performance

-

Understanding Guide Valves: Their Role in Fluid Dynamics with 2023 Industry Insights

-

Top Insights on Through Valve Technology for 2025 and Beyond

(780) 669-9420

(780) 669-9420