Blog

- Home

- Blog

Understanding Guide Valves: Their Role in Fluid Dynamics with 2023 Industry Insights

In the realm of fluid dynamics, guide valves play a pivotal role in ensuring efficient flow control and system stability. These specialized valves are designed to direct the flow of fluids within a system, making them essential components in various industrial applications, from water treatment plants to chemical processing facilities. As the industry continues to evolve, understanding the intricacies of guide valves, including their design, functionality, and performance metrics, becomes paramount for engineers and operators alike.

This article delves into the fundamental aspects of guide valves, elucidating their significance in managing fluid movement while optimizing system performance. We will explore how advancements in technology and materials have influenced the development of guide valves, offering insights into their operation and the innovative solutions available in 2023. By examining recent industry trends and practical applications, we aim to provide a comprehensive understanding of guide valves and their indispensable contribution to fluid dynamics.

The Fundamentals of Guide Valves in Fluid Dynamics

Guide valves play a crucial role in the realm of fluid dynamics, serving as essential components for controlling the flow of liquids and gases in various systems. These valves are designed to direct fluid movement efficiently, ensuring optimal performance and precision within pipelines, pumps, and various industrial applications. By regulating the pressure and flow rate, guide valves help maintain the integrity of the entire fluid transport system, minimizing energy loss and enhancing operational efficacy.

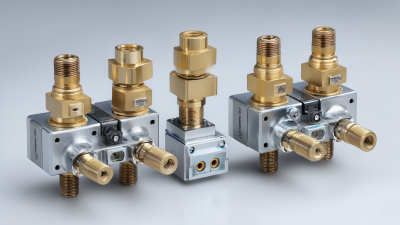

The fundamentals of guide valves hinge on their ability to manage fluid direction through strategic openings and closures. Various types of guide valves, including globe, gate, and check valves, are utilized depending on specific requirements of the system. Understanding the mechanics behind these valves, such as their design and functional characteristics, is vital for engineers and operators aiming to optimize fluid dynamics. Recent industry insights from 2023 highlight advancements in materials and technology that enhance the efficiency and reliability of guide valves, offering improved performance in demanding environments. This evolution underscores the necessity of continued innovation to address the challenges posed by modern fluid systems.

Key Functions of Guide Valves in Controlling Fluid Flow

Guide valves play a critical role in controlling fluid flow, acting as essential components in various industrial applications. By directing the movement of fluids through a system, these valves ensure optimal performance and efficiency. Recent industry insights indicate that the global market for guide valves is projected to grow at a CAGR of 6.5% from 2023 to 2030, driven by increasing demand in sectors such as oil and gas, chemical processing, and water treatment. The precise control offered by guide valves is crucial in maintaining desired flow rates and pressures, ultimately enhancing the reliability of fluid systems.

The key functions of guide valves include flow regulation, pressure control, and direction alteration of fluids. According to a 2022 report from the International Journal of Fluid Dynamics, properly calibrated guide valves can reduce energy consumption by up to 20% in industrial applications. They facilitate smooth transitions and prevent surges or backflows, which can cause system inefficiencies or damage. As industries continue to prioritize sustainability and cost-effectiveness, the role of guide valves in optimizing fluid dynamics becomes increasingly vital, making them integral to modern engineering solutions.

Understanding Guide Valves: Their Role in Fluid Dynamics with 2023 Industry Insights

| Dimension | Value | Unit |

|---|---|---|

| Flow Rate Capacity | 500 | liters/min |

| Max Operating Pressure | 10 | bar |

| Temperature Range | -20 to 120 | °C |

| Weight | 15 | kg |

| Material | Stainless Steel | N/A |

| Installation Type | Flanged | N/A |

Recent Innovations in Guide Valve Technology for 2023

Recent advancements in guide valve technology are paving the way for enhanced efficiency in fluid dynamics, particularly in the renewable energy sector. Innovations such as smart actuators and real-time monitoring systems are improving responsiveness and control, allowing for more precise fluid management in solar and wind energy applications. These advancements not only streamline operations but also minimize waste, enabling facilities to maximize production and reduce costs.

However, the integration of these technologies presents challenges. The complexity of new systems requires substantial investment in training and infrastructure, which can be a barrier for smaller companies. Additionally, ensuring compatibility with existing systems remains a hurdle. As the industry moves forward, balancing these opportunities with the inherent challenges will be crucial for driving the widespread adoption of innovative guide valve solutions in renewable energy technologies.

Challenges and Solutions in Guide Valve Applications

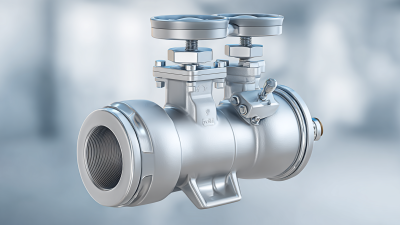

Guide valves play a crucial role in fluid dynamics, offering precision control over flow direction and pressure regulation in various applications. However, their implementation often comes with specific challenges that can hinder system performance and efficiency. One common issue is the accumulation of debris and sediment within the valve, which can lead to blockages and prevent the valve from operating effectively. Regular maintenance and the integration of filtration systems can mitigate this problem, ensuring smoother operations and prolonging the lifespan of the valve.

Another significant challenge in guide valve applications is achieving optimal sealing to prevent leaks. As fluids pass through the valve, it is essential to maintain a tight seal to avoid losses and maintain overall system integrity. This requirement necessitates the use of high-quality sealing materials and innovative design strategies that enhance reliability. Recent industry insights suggest that advances in materials science, such as the development of resilient elastomers and composites, are proving beneficial in creating more effective sealing solutions. Implementing these advancements can address leakage concerns and improve the overall performance of guide valves in demanding environments.

Future Trends in Guide Valve Design and Usage in the Industry

The guide valve industry is poised for significant evolution, shaped by emerging trends and developing technologies. A key focus in 2023 is the increased demand for efficient and reliable fluid management systems across various sectors. The control valve market is projected to experience robust growth, expanding from USD 7.8 billion in 2024 to USD 15.5 billion by 2032, reflecting a compound annual growth rate (CAGR) of 9.1%. This surge is indicative of a broader shift towards automation and precision control in fluid dynamics, which guide valves play a crucial role in.

As we look towards the future, innovative designs in guide valve technology are becoming critical. Companies are investing in startups that specialize in smart valve solutions and advanced materials. The growing adoption of generative AI demonstrates the industry's commitment to enhancing operational efficiency and predictive maintenance. This is exemplified by a recent rise in startups focusing on digital transformations in fluid dynamics, alongside the expansion of traditional valve markets.

Tips: Embrace digital transformation to improve efficiency in fluid management. Consider investing in smart valve technologies that leverage AI for predictive maintenance and operational optimization. Stay informed about market trends and innovate your valve designs to meet the evolving needs of the industry.

Related Posts

-

Understanding the Role of Guide Valves in Modern Hydraulic Systems

-

Understanding Single Valve Systems: The Key to Efficient Fluid Control in Modern Engineering

-

Understanding T Valves: The Key Component in Plumbing and HVAC Systems Explained

-

Exploring the Advantages of Single Valve Systems for Efficient Fluid Control

(780) 669-9420

(780) 669-9420