Blog

- Home

- Blog

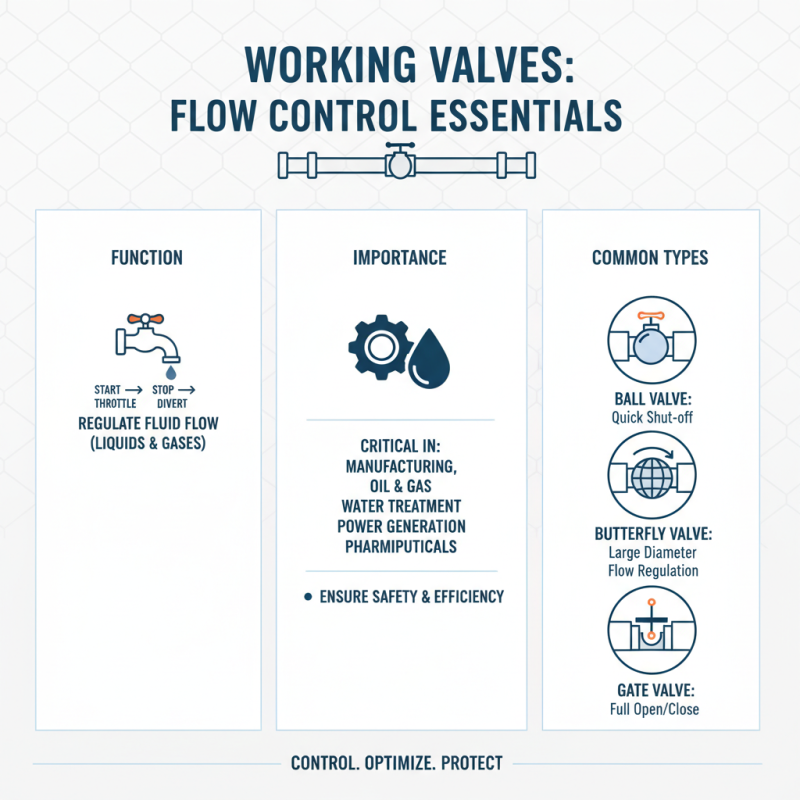

What is a Working Valve and How Does It Function?

A working valve is a crucial component in various systems, controlling the flow of fluids. It plays a significant role in pipelines, HVAC systems, and industrial applications. The operation of a working valve can greatly impact overall efficiency. Understanding its function is essential for maintenance and operation.

In simple terms, a working valve opens and closes to allow or block fluid passage. This mechanism helps regulate pressure and flow. However, many people overlook the details in how valves operate. Each type has a specific role. Some control gas, while others manage liquids.

Consider a working valve in a home heating system. It affects temperature regulation. If it malfunctions, comfort levels drop. Moreover, not all working valves are created equal. Some may fail under pressure or age. Regular checks can prevent costly repairs. Often, we do not prioritize these checks, leading to unexpected issues later.

Definition of a Working Valve and Its Importance in Systems

A working valve plays a crucial role in various systems, controlling the flow of liquids and gases. Its definition is straightforward: a device designed to regulate, divert, or control the flow of fluids. Efficient valve operation is essential for maintaining system integrity, safety, and performance. Industry reports indicate that over 25% of system failures can be traced back to valve malfunctions. Thus, understanding their importance is vital.

Valves are not just simple mechanical devices; they require regular maintenance. Neglecting this can lead to leaks or valve stickiness, impacting overall efficiency. A 2021 study showed that poorly maintained valves could increase operational costs by up to 30%. Regular inspection is necessary for achieving optimal performance.

**Tips:** Check valve seals periodically to prevent leaks. When replacing a valve, consider the system’s specific needs. Not all valves fit every purpose, and choosing the wrong type can cause significant issues. Remember, even small components play a giant role in system functionality.

Types of Working Valves and Their Specific Applications

Working valves play a crucial role in various industries. Their function is to control the flow of fluids in a system. Different types of working valves exist, each designed for specific applications.

Gate valves are often used in oil and gas operations. They allow for the complete shut-off of fluid. These valves are ideal for on-off control but not for flow throttling. Ball valves, on the other hand, are versatile and good for quick shut-off. They provide excellent sealing, making them suitable for both liquids and gases.

Tip: Regular maintenance of these valves is essential. A malfunctioning valve can lead to system inefficiencies. Always check for leaks and wear over time.

Butterfly valves are common in water treatment facilities. They are lightweight and compact, making installation easier. However, they may not seal as tightly as other valve types. Careful selection based on system requirements is necessary.

Tip: Evaluate your application carefully. Choosing the wrong valve can impact performance and energy costs. Understand the specific needs of your system before making a decision.

Mechanism of Operation: How a Working Valve Functions

A working valve plays a critical role in controlling fluid flow. Its operation relies on a simple yet effective mechanism. When a valve is actuated, it opens or closes to manage the passage of liquids or gases. This process can be manual or automated, depending on the system's requirements.

Inside the valve, there are typically several components: a body, seats, and internal mechanisms. These parts work together to facilitate smooth operation. For instance, a rotating disk or sliding gate might act as the closure element. Even small imperfections in these components can lead to inefficiencies. Thus, regular maintenance is necessary.

The valve's function varies significantly based on its design. Some valves are designed for quick opening and closing, while others might offer precise flow regulation. This variability can sometimes lead to confusion in application. Understanding each valve's purpose is crucial for optimal performance. It is not uncommon to observe maintenance challenges. Recognizing these potential issues is the first step toward effective use.

Working Valve Functionality Overview

This bar chart represents the flow rates of different types of working valves, illustrating their operational capabilities. Type A has a flow rate of 150 L/min, while Type B peaks at 200 L/min, and Types C and D show flow rates of 120 L/min and 170 L/min respectively.

Common Materials Used in Working Valves for Durability

Working valves are essential components in various industrial applications. They regulate fluid flow and maintain pressure. To ensure their longevity, durability is key.

Common materials used in working valves include stainless steel, brass, and plastic. Stainless steel is resistant to corrosion and high temperatures. It’s a popular choice for harsh environments. Brass offers good strength and is often used in water applications. However, it may corrode over time. Plastic valves are lightweight and resistant to chemicals. Yet, they may have lower pressure ratings.

Choosing the right material is crucial. Engineers weigh the pros and cons of each. Sometimes, the best choice isn’t clear. There are trade-offs between durability and cost. It's important to assess the specific application. Knowing the environment helps in making informed decisions.

Maintenance Best Practices for Ensuring Valve Efficiency

Maintaining valve efficiency is critical for optimal performance in any system. Regular inspections should be part of your routine. Look for any signs of wear. A leaking valve can lead to bigger problems. Small leaks often escalate if left unchecked. Cleanliness is vital. Dirt and debris can accumulate and cause malfunction.

Lubrication is essential to keep moving parts functioning smoothly. Yet, it can be challenging. Over-lubrication can attract more dirt. Under-lubrication may cause increased friction. Find a balance. Inspect seals and gaskets frequently, as these parts tend to wear out. Consider replacing them at regular intervals.

Documentation is also necessary. Keep a maintenance log. Record any repairs or replacements. This practice helps identify recurring issues. It can illuminate patterns that need addressing. Sometimes, despite all efforts, unexpected failures occur. Use these moments to learn and improve your maintenance strategy. Adopting a proactive mindset toward maintenance will enhance overall valve efficiency.

Related Posts

-

How to Choose the Right Working Valve for Your Project?

-

Top 10 Guide Valves: Essential Insights and Data for Optimal Performance

-

2025 Top Valve Applications You Need to Know for Future Innovations

-

Exploring the Future: Top Valve Engineering Innovations of 2025

-

Top Benefits of Engineered Valves for Industrial Applications

-

How to Effectively Control Flow Through Valve Systems for Optimal Performance

(780) 669-9420

(780) 669-9420